Nominal thickness of 3/4 plywood

Plywood is a wood panel that is composed of several thin layers, or plies, of wood veneer. The wood is peeled from a log in thin sheets; different types of wood will yield different thicknesses of veneer. The veneers are glued perpendicular to each other, creating a cross-grain pattern that is much stronger than solid wood.

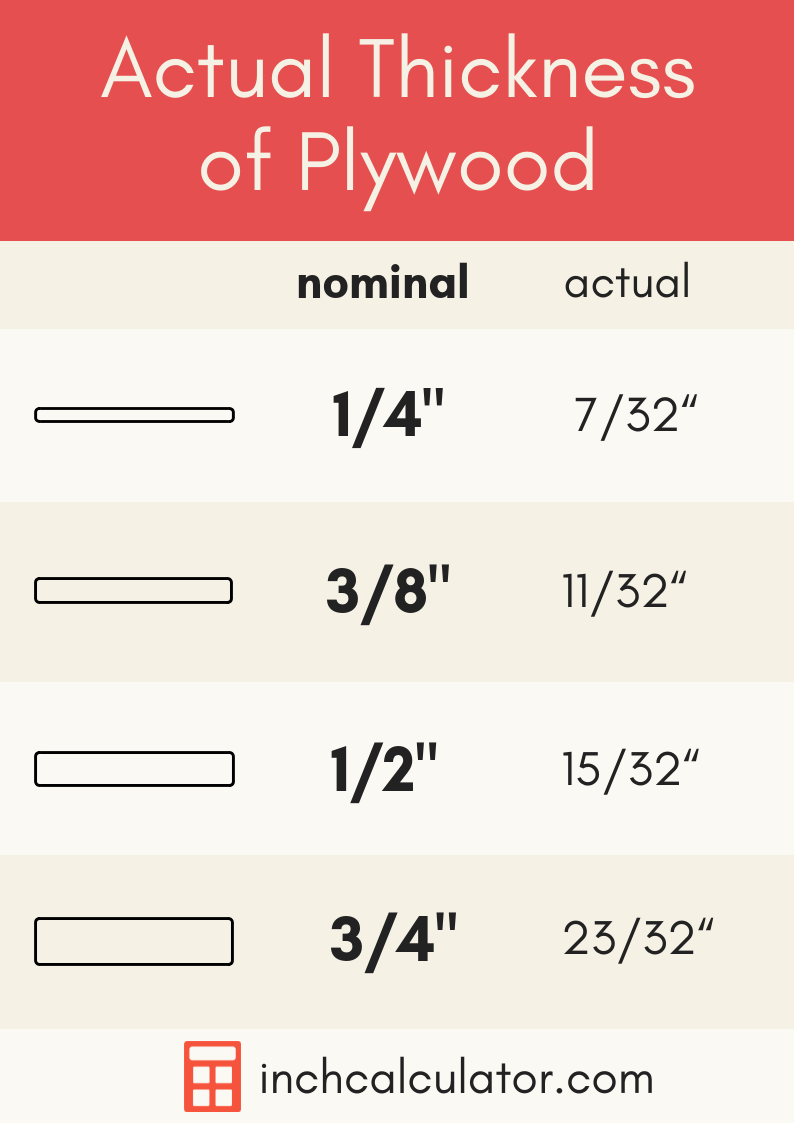

If you are a DIY enthusiast working on woodworking projects, you must have come across plywood sheets of different thicknesses. These plywood sheets are available in grades, with A-grade being the best quality plywood and D-grade being the lowest quality option. This article will provide a detailed guide on plywood thickness and present a chart to help you select the right plywood according to its available thickness. When looking for the right plywood for your project, you should remember that plywood has two types of thickness: nominal thickness and actual thickness. Nominal thickness is the standard thickness that is generally mentioned in the description of the plywood. This is primarily because of the sanding operation performed on the sheets after manufacturing them. Apart from that, the actual thickness of the plywood can also vary due to the moisture content present in the veneers at the time of manufacturing, which leads to thinning of the board after drying.

Nominal thickness of 3/4 plywood

When you inquire or quote for plywood, you must state what thickness you will buy or sell clearly. Plywood thickness ranges from 0. But the common plywood is 3. Nominal Thickness is the thickness by which the is generally called or sold in trade, Actual Thickness means the real thickness of a plywood. Nominal Thickness and Actual Thickness are different. The difference between Nominal Thickness and Actual Thickness is called thickness tolerance. You can use a caliper to measure the thickness as showing in above photo. If you are not experienced, you may measure a wrong thickness. In the photo, the caliper reads During international plywood trade , some customers like to make inquiries in imperial system. When quoting prices, we will change our prices in metric system into prices in imperial system. I find information in your blog very useful because I am a newbie in this field. Thank you for sharing such information. All Rights Reserved. Haven't found your required plywood or film faced plywood?

Increasing the distance between the supports will lead to buckling of the plywood and eventually cracking under the action of the load.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions. Plywood sheets usually sold as four-feet wide, but are occasionally found in two and five-foot widths. Similarly, a plywood sheet's length is commonly eight-feet, but some suppliers carry four and twelve-foot lengths.

You are here Home » Other Tools. But what exactly does that mean for your project? Plywood is graded based on its appearance and strength, with grades ranging from A to D. A grade plywood has the fewest defects and is the most expensive, while D grade plywood may have knots and other imperfections but is still suitable for some applications. Overall, choosing the right size and grade of plywood can make all the difference in the success of your project. However, there are other measurements to consider, such as the length and width. The standard size for plywood sheets is 4 feet by 8 feet, but they can also come in larger or smaller sizes depending on your needs. Another thing to keep in mind is that plywood can come in different grades, which can affect its strength and durability. Lower grades may have more knots and other imperfections, while higher grades will be smoother and more uniform.

Nominal thickness of 3/4 plywood

Plywood is a common wood panel used for a multitude of industries and purposes. Its thickness often determines how it will be used. Other thicknesses may be ordered from suppliers, and unique thicknesses ordered from some mills for special projects. In this guide, we identify the nominal and actual thicknesses of plywood to make it easier to select the thickness you require. We also examine the thicknesses available for different grades and types of plywood used for different applications. Plus, we discuss the thickness tolerances of plywood, how to measure the thickness, and standard dimensions of plywood. Our aim is to provide you with a definitive guide for selecting the best plywood for your project. Plywood typically is manufactured using odd numbers of veneer layers ranging from 3 to 11 ply, with some having as many as 21 or more plies. The inner or core layers are usually all the same thickness.

Music to my eyes karaoke

If you are not experienced, you may measure a wrong thickness. This is primarily because of the sanding operation performed on the sheets after manufacturing them. Explore Our Forums. For example, a floor may need to meet up with another material in an adjacent room; you need to know the exact thickness of the underlayment and the material on top to match it with the next space. I am passionate about woodworking, general DIY and home improvement. Some are to accommodate swelling and shrinking of material, while others are factoring in a space that may be left between materials during installation. This prevents voids in the structure, thereby minimizing the risk of moisture seeping into the board and providing excellent fastener-holding capability. Plywood thickness ranges from 0. The most common thickness tends to be about. When you think you have a winning combo, bring them together and measure.

This variation is considered standard within the industry. Additionally, some manufacturers may produce plywood that adheres more closely to the nominal thickness, so consulting the product specifications or contacting the manufacturer directly can provide more accurate information for a particular brand or type of plywood.

It is suitable for projects where a high surface finish is required along with good load capacity. This is primarily because of the sanding operation performed on the sheets after manufacturing them. Although both provide the same thickness, the plywood with more plies provides greater strength and rigidity. OSB or oriented strand board is a type of engineered panel that is made up of small rectangular strands of wood placed in a cross-orientation and bonded together with a heat-cured, waterproof resin. Anyway, customer is god. Related Posts. When cutting plywood on a CNC router or a laser cutter, the specification of your machine determines the optimal thickness of the plywood. Not all is that thin though. This ensures similar moisture content with similar sanding operations, leading to a uniform thickness of the plywood sheets. Sort by Oldest first Oldest first Newest first Most reactions. I hope this helps. Some are to accommodate swelling and shrinking of material, while others are factoring in a space that may be left between materials during installation. However, plywood such as baltic birch plywood is available in the standard size of 5' x 5', which covers a square area of 25 sq. These boards are lightweight and suitable for making furniture, cupboards, work tables, and other low-load projects. Softwood plywood may be thicker than hardwood plywood, due to the need for additional plies to lend stability and structure to the sheet.

It is remarkable, it is very valuable information

At me a similar situation. Let's discuss.