Lathe machine diagram easy

In the Mechanical Engineering field Lathe machine plays an important role in Manufacturing. In this article, I am going to discuss the Lathe machine in detail. Definition of Lathe Machine. Head Stock.

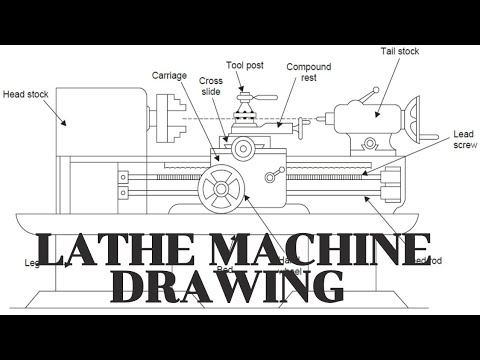

Working Principle : The lathe is a machine tool which holds the workpiece between two rigid and strong supports called centers or in a chuck or face plate which revolves. The cutting tool is rigidly held and supported in a tool post which is fed against the revolving work. The normal cutting operations are performed with the cutting tool fed either parallel or at right angles to the axis of the work. The cutting tool may also be fed at an angle relative to the axis of work for machining tapers and angles. Construction : The main parts of the lathe are the bed, headstock, quick changing gear box, carriage and tailstock. Bed : The bed is a heavy, rugged casting in which are mounted the working parts of the lathe. It carries the headstock and tail stock for supporting the workpiece and provides a base for the movement of carriage assembly which carries the tool.

Lathe machine diagram easy

The Mechanical engineering stream has seen some tremendous machines invented and modified all these years. One of the remarkable machines that completely revolutionized the way we perform operations on metal or wood is the Lathe Machine. Lathe is a machine tool commonly used in all industrial applications. Now, a machine tool is power-driven and designed to move a sharp cutting tool against a rigidly held workpiece material or vice versa to remove material from the workpiece. In this article, we will discuss the definition, parts, working principle, and types of lathe machines. You will learn the operations that are performed on the machine in brief. A lathe machine is a machine tool that is used to remove unwanted material from a rotating workpiece in the form of chips. This is accomplished with the use of a tool that traverses across the workpiece and feeds into it. The machine is used to accomplish all fundamental operations, including drilling, sawing, tapping, and turning, among others, with the aid of various tools located in the work area. Andrei Nartov, a Russian engineer, created one of the earliest lathes in It featured a carriage for holding mechanical cutting tools and a system of gears. In the s, servomechanisms were applied to the numerical control of lathes and other machine tools, which were frequently linked with computers to produce computerised numerical control CNC. Both manually driven and computer numerical control, or CNC, lathes are used in the industry today. You may be wondering about the various parts of this ancient machine tool. This section helps you learn all the parts that are responsible for the work done on the machine.

Purchase Now.

The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. In this article, you will learn about different parts of the lathe and their functions. The headstock of a lathe is the side where we fix the workpiece. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. In a normal bench lathe, there are two spindles.

The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. In this article, you will learn about different parts of the lathe and their functions. The headstock of a lathe is the side where we fix the workpiece. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. In a normal bench lathe, there are two spindles. One belongs to the headstock and the other belongs to the tailstock. So, each spindle is known as the headstock spindle and toolstock spindle. Chuck is a type of clamp that we use to hold the workpiece in radial symmetry.

Lathe machine diagram easy

The lathe machine is one of the oldest machine tools in history. An Englishman named Henry Maudslay is credited for designing the lathe machine in As you may know, the lathe machine is a machine tool primarily used for shaping metal or wood. It rotates the workpiece around an unmoving cutting lathe tool. It removes undesired parts of the material and leaves behind a newly shaped workpiece. The lathe machine is simply an impressive piece of equipment thanks to its different parts that work well together. Continue reading below to learn more about the parts and functions of a lathe machine. There are six major parts of a lathe machine. These are the bed, the head stock assembly, the main spindle, the tail stock, the carriage, and overload safety devices.

Traduction si no esta

The tailstock is a moveable casting opposite to the headstock that is mounted on the guideways on the bed. Neutral Position. Head Stock. It is utilised for wood polishing, spinning, centring, and machining. Counter Boring. Name required. This remains common to all types of lathes with some minor changes. October 14, Well summarized information. Cross slide. The carriage needs power from the operator, so we use the lead screw to transfer power from headstock to carriage. Round Groove. Its a good fundamental to know about lathe machine thanks. Devesh Zagade July 16, Good information.. Ashok gupta August 25, This note is very easy for uptu exam thank sir alot thank sir.

Last Updated on February 7, by Charles Wilson. Hence, before laying your hands on it, familiarizing yourself with the different parts of a lathe machine and its functions should be your first assignment.

The pointed end of it is placed touching the other end of the workpiece to avoid an abrupt stop in rotation and reduce friction. It is similar to the Turret lathe where the capstan is used for the mass manufacture of lightweight workpieces. The biggest advantage is the ability to cut threads with ease on the machine. Advantages of Lathe Machine A machine to leaves a legacy and remain used throughout history should have some remarkable advantages. And there are two major components in the carriage. Tool room lathe machine. Well summarized information. Speed Lathe As the term speed implies, the spindle of the headstock is revolving at a rapid rate. Saurav singh April 30, Thnx very helpful notes. Disadvantages of Lathe Machine As the advancements in technology made so many improvements to these ancient machines, the disadvantages of these machines became evident. I also suggest all the readers to go through the below link. A lathe machine is a machine tool that is used to remove unwanted material from a rotating workpiece in the form of chips. Four Way Tool Post. Lathe Machine Parts You may be wondering about the various parts of this ancient machine tool. However, according to their construction and design we can classify the lathes as follows: […].

And how in that case to act?

In my opinion you are not right. I can prove it. Write to me in PM, we will talk.

The duly answer