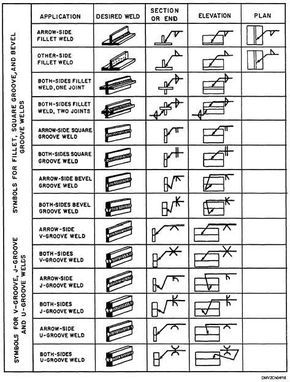

Welding symbols chart

Next to Welding Certification Welding symbols are one of the most misunderstood concepts in the welding profession, welding symbols chart. A lot of welders get by for their entire careers without having a good understanding of welding symbols.

It should be understood that these charts are intended only as shop aids. The only complete and official presentation of the standard welding symbols is in AWS A2. Suitable for framing or displaying on your shop wall, the welding symbol chart is 11 x 17 inches. Click on the image to download the full size chart. With this chart, you can easily convert between fractional, decimal, and metric sizes for all of your shop needs! Suitable for framing or displaying on your shop wall, the decimal chart is 11 x 8.

Welding symbols chart

This guide will help you to understand different welding blueprint symbols and signs. We will point out the weld callouts with example images and list of options for each aspect of the welding symbol. When designing parts for general metal fabrication, welding symbols, and detailed callouts will be required to communicate design intent and requirements effectively to manufacturers. These callouts will be found on the technical drawings or blueprint of the assembly, also known as a weldment, and will specify weld geometry and its associated size and length requirements. When interpreting a print, the welding symbol will contain all the appropriate information necessary to perform the proper weld on the part. Welding symbols, which are different than weld symbols, contain information such as what weld symbol is being used fillet, bevel, square butt, plug weld, etc. Welding symbols are a menagerie of information, and the combinations of designs and choices that can be made are significant. Example of basic welding symbols. Types of Welding. There exist a variety of welding processes to utilize, but ultimately welding processes are generally agnostic to the process, so long as the symbol callouts are satisfied during the fabrication process. Weld Procedures are generated and used if specific welding processes are required, and these go even further to specify the filler material, any preheat requirements for the part, as well as heat input and feed rates allowed during the welding process.

The technical storage or access that is used exclusively for anonymous statistical purposes. With this chart, you welding symbols chart easily convert between fractional, decimal, and metric sizes for all of your shop needs! A lot of welders get by for their entire careers without having a good understanding of welding symbols.

.

Welding symbols guide welders in preparing, welding, and finishing weld joints. All the information you need as a welder is in the welding symbol. Welding symbols ensure the welder knows what the engineers and designers of the product intended for the welding. A welding symbol is a picture with multiple parts that contain information to inform the welder about how to proceed. This section aims to break down the structure of the welding symbol, making it easier to digest and understand. A welding symbol is what you see above and contains the arrow, reference line, and tail. You place a weld symbol on the reference line of a welding symbol to indicate what type of weld you require. The reference line is the main component of the welding symbol and contains the bulk of the information for the welder. The ISO standard uses a dashed line underneath the reference line to hold the information for a weld on the opposite side of the weld joint.

Welding symbols chart

When you see an engineering fabrication drawing, you will notice several welding symbols on the drawing. Weld symbols and welding symbols enable the designer to communicate and convey the required welding details to the fabricator. In the absence of these symbols, the designer must place explanation notes on the drawing for each weld joint, which consumes space and time and lacks clarity.

Hoskins funeral home gfw nl obituaries

The Bevel Angle The bevel angle is the shape of the bevel between the two connecting parts at the weld joint. Weldmonger Tungsten. Functional Functional Always active The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network. Suitable for framing or displaying on your shop wall, the decimal chart is 11 x 8. The American Welding Society AWS has a comprehensive list of basic welding symbols that can be seen below, as well as general groove welding symbols. The notation to be placed in the tail of the symbol indicating these data is to be established by each user. Not consenting or withdrawing consent, may adversely affect certain features and functions. If notations are not used, the tail of the symbol may be omitted. The "groove" is created by either a tight fit or a slight separation of the edges. Flowmeters Dual and Single Flowmeters for welding and purging. The leg size is written to the left of the weld symbol. This size effects the overall strength of the weld and can also affect how much distortion the part experiences during the welding process as a direct result of the amount of heat input.

Last Updated on Jul 17 Do you need to study on the run? Download the symbols chart as.

The reference line is not always double sided or single sided — it can have two different types of information on the top and bottom, which implies that the top of the joint to be welded will receive a different type of weld than the bottom side. This arrow does not always have a straight section, it may be angled to pinpoint the exact location of the weld depending on geometry. Conclusion Welding blueprint symbols and signs are of paramount importance in the realm of product design and mechanical engineering, as they provide a standardized visual language that effectively communicates the specifications and requirements for various types of welds and weld joints. The amount of separation, if any, is given on the weld symbol. By far the two most important weld symbols to know are the fillet weld symbol and the groove weld symbols. Within this reference line, all pertinent welding information will be displayed. Additionally, weld metal specifications and standardized symbols for weld joints are indispensable for ensuring that the correct amount of material is used and that the proper joint configuration is achieved. Functional Functional Always active The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network. Tig Fingers. The horizontal line is an essential component of welding symbols, providing a reference line for all other welding symbols and dimensions. There are a variety of other weld symbols, such as the spot-welding symbol , which is also used as an informal tack welding symbol, the plug weld symbol which can also be used to denote a straight slot weld , and the most common fillet weld symbol. These symbols, which adhere to guidelines set forth by the American Welding Society, facilitate clear communication among engineers, welders, and fabricators, ensuring a smooth transition from the design phase to the manufacturing phase.

I think, that you commit an error. I can defend the position. Write to me in PM, we will communicate.

I protest against it.

I think, that you are mistaken. I suggest it to discuss.