Usfd manual

Ultrasonic testing of rails was introduced over Indian Railways during early 60s.

Disclaimer: This Compilation is for educational reference only. For details refer original correction slips. Ultrasonic testing of rails was introduced over Indian Railways during early 60s. From a humble beginning, this technique has graduated itself to an extent that today it is one of the most powerful tools of preventive maintenance of the permanent way. During the last 40 years of its existence, a large number of testing procedures, specifications, guidelines and criteria have been issued from time to time based on the experience gained. The advent of fracture mechanics concept coupled with state of the art steel making technology has thrown open a new dimension in the periodicity of ultrasonic examination. The rate of crack propagation and fracture toughness characteristics of rails can be experimentally found which determine the critical crack size.

Usfd manual

.

Repetitive rail fractures of same rolling mark, usfd manual. The re-welded joints shall be scanned ultrasonically again with the same set of acceptance criteria to ensure usfd manual from any harmful defects. SR of 30 Kmph can be relaxed to normal after providing joggled fish plates with two far end tight bolts one on each side with champhering of holes.

.

Ultrasonic testing of rails was introduced over Indian Railways during early 60s. From a humble beginning, this technique has graduated itself to an extent that today it is one of the most powerful tools of preventive maintenance of the permanent way. During the last 40 years of its existence, a large number of testing procedures, specifications, guidelines and criteria have been issued from time to time based on the experience gained. The advent of fracture mechanics concept coupled with state of the art steel making technology has thrown open a new dimension in the periodicity of ultrasonic examination. The rate of crack propagation and fracture toughness characteristics of rails can be experimentally found which determine the critical crack size. Based on the above knowledge and experience, it was considered necessary to assimilate the entire information on ultrasonic examination of rails and present in the form of a manual so as to guide the ultrasonic personnel in testing, interpretation and decision-making. Subsequently, a revision was issued in in view of the experience gained in the field of USFD testing and maintenance practices.

Usfd manual

Disclaimer: This Compilation is for educational reference only. For details refer original correction slips. Ultrasonic testing of rails was introduced over Indian Railways during early 60s. From a humble beginning, this technique has graduated itself to an extent that today it is one of the most powerful tools of preventive maintenance of the permanent way. During the last 40 years of its existence, a large number of testing procedures, specifications, guidelines and criteria have been issued from time to time based on the experience gained. The advent of fracture mechanics concept coupled with state of the art steel making technology has thrown open a new dimension in the periodicity of ultrasonic examination. The rate of crack propagation and fracture toughness characteristics of rails can be experimentally found which determine the critical crack size.

Amy brenneman desnuda

Mainly hydrogen accumulation and non-metallic inclusions cause this defect. To verify the calibration, put probe on top of rail head, the back peak position will be at 5. Condition of Audio Alarm Adequate traffic block should be granted for removal of DFWR welds. For proper maintenance after expiry of the guarantee period, railway should make proper arrangements for half yearly repairs of electronic and mechanical parts either under AMC with the manufacturer of the equipment or may develop suitable departmental facilities. Way Code To FR no. The monitoring special shall be accompanied by following officers from the railway and division:. The pattern obtained on defective rails will be as given in Fig. Move the probe to and fro from 5 mm dia hole and set the. Clusters of non-metallic inclusions and abnormal vertical service stresses are the factors responsible for this defect. Note : Procedure to be followed for adjustment in sensitivity setting on account of variation in rail temperature: Following procedure shall be used for adjustments in sensitivity setting of Ultrasonic Rail tester on account of variation in rail temperature before starting the testing of rails. Identification of defect is done electronically according to laid down logics. For the sequencing, real time report can be used as in this report number of defects will equal number of paint marks.

.

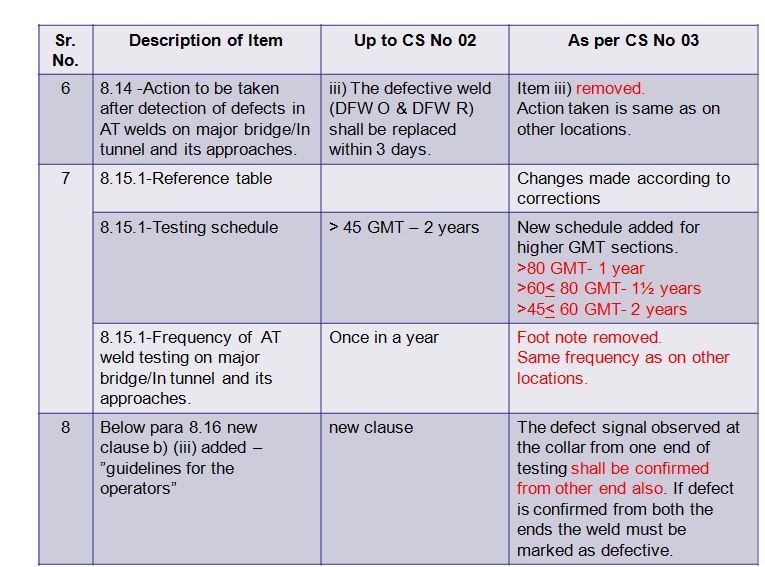

Hence, it is essential to ensure full charging of the battery. Condition of shoes of probes Un-even wear. To FR no. Annexure VI Para Type Frequency No. Short pitch 2. In addition hand testers of some designs are also being used. Limitations of ultrasonic flaw detection of rails USFD procedure has been designed to detect defects smaller than above mentioned width. This equipment has also been provided with a threshold arrangement, LED display and audio alarm in addition to the CRT screen. Place Gate over it and read the beam path, depth shall be mm. Bs 1 Bs 1 Test the weld with sensitivity setting as mentioned in para 8. Ultrasonic testing of rails was introduced over Indian Railways during early 60s.

Certainly. And I have faced it. Let's discuss this question.

I consider, that you are not right. I am assured. Let's discuss. Write to me in PM, we will communicate.