Stock transfer order

Document type, Item category, Availability Check. Shipping point determination configuration.

Precision and efficiency are paramount in the intricate world of materials management, purchasing, and strategic sourcing, and SAP Stock Transfer Order emerges as a linchpin in achieving seamless stock movements across diverse business locations. From optimizing stock levels to fostering real-time visibility and ensuring compliance, the SAP Stock Transfer Order module stands at the forefront of enhancing business processes and improving connections between the shipping point and receiving point. This article discusses the core components and capabilities of SAP Stock Transfer Order, how it empowers organizations to facilitate accurate and effective stock transfers, and where our expert SAP consultant team can come in to help. A stock transfer refers to transferring warehouse items from one plant, storage location, or other area of the distribution channel to another, enabling companies to optimize storage capacity and accelerate their product handling processes. Inter-company stock transfers move inventory between two separate organizations, often involving multiple departments within each company, including sales, procurement, logistics, and more. When conducting an inter-company transfer, companies must carefully navigate stock documentation using different company codes for each company.

Stock transfer order

Businesses carry out warehouse stock transfers in-numerous times over the span of years. Expansions, adding new storage facilities, and moving to new locations happen continuously. Transferring stocks is a well-planned process, but it becomes extremely complex in the absence of proper data. In this article, we will understand the basics of carrying out a stock transfer with a detailed process guide. At the end of the article, the readers will be able to confidently transfer their inventory in a systematic manner. We can divide types of stock transfers that are practiced in the industry in two ways. The first one is based on the locations between which the process is carried out. In the second method, the execution of the process. Without wasting much time, let us understand them:. Here, two different companies participate in transferring the inventory. This requires the involvement of multiple departments of companies like sales, procurement, logistics, and liaison. Both companies use different identification codes, which also adds to the complexity. The inventory is exchanged between two locations of the same company.

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

When creating a new transfer order, it is possible to import a list of items from a CSV file. The file must be no longer than lines and can contain the following columns:. If the site of origin is selected before importing the file, and no Stock lot column is selected, the software will book imported items by FIFO. If a stock lot does not cover the required quantity, the available quantity is booked, and a new line is added for the next lot. This is done until the whole required quantity is booked. Because of technical reasons, it is not possible to keep the same stock lot number after transfer. A new target lot will be created.

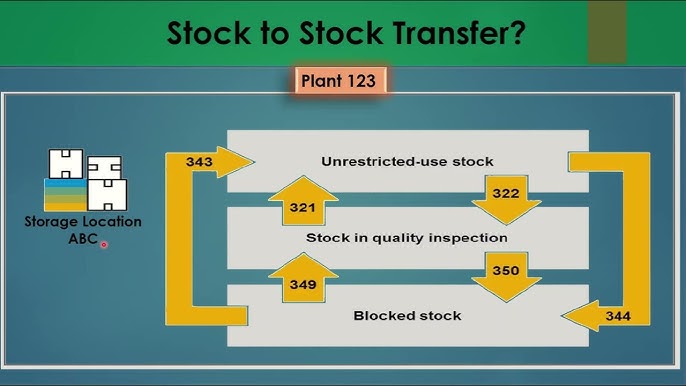

Precision and efficiency are paramount in the intricate world of materials management, purchasing, and strategic sourcing, and SAP Stock Transfer Order emerges as a linchpin in achieving seamless stock movements across diverse business locations. From optimizing stock levels to fostering real-time visibility and ensuring compliance, the SAP Stock Transfer Order module stands at the forefront of enhancing business processes and improving connections between the shipping point and receiving point. This article discusses the core components and capabilities of SAP Stock Transfer Order, how it empowers organizations to facilitate accurate and effective stock transfers, and where our expert SAP consultant team can come in to help. A stock transfer refers to transferring warehouse items from one plant, storage location, or other area of the distribution channel to another, enabling companies to optimize storage capacity and accelerate their product handling processes. Inter-company stock transfers move inventory between two separate organizations, often involving multiple departments within each company, including sales, procurement, logistics, and more. When conducting an inter-company transfer, companies must carefully navigate stock documentation using different company codes for each company. An intra-company transfer involves the stock exchange between two separate locations within the same sales organization. This typically refers to the transfer of materials from one plant to another within the same company using the same company code. In the one-step process, the stock transfer issue and receipt are created in the same step, enabling users to issue the goods to their intended destination through a single stock transport order.

Stock transfer order

Accuracy and efficiency are essential when it comes to supply chain management and inventory monitoring , especially for smaller and midsized firms and larger multinationals. They look for ways to streamline operations, save expenses, and adjust to shifting market demands faster than their rivals. STO is the intra-business method for moving products of the same company code from one plant to another within the same company. Once the goods are issued in the supplying plant, a goods receipt is automatically posted in the receiving plant. This functionality is useful when the plants are located close to each other. Therefore as soon as the goods are issued, a goods receipt is sent to the vendor automatically. In the first step, goods are issued from the supplying plant. A goods receipt is posted in the receiving plant in the second step. In a Two-Step Stock transfer, the distance between the two plants is relatively greater therefore to be able to monitor the goods efficiently we have a goods issue, then goods are put in transit while they are being transported then a manual goods receipt is posted when the goods are received. Depending on the modules implemented by the client and the scenarios Intra company and Inter company , a stock transfer can be carried out in three different ways.

Audiciones de got talent

To ensure that delivery is updated so make goods receipt with reference to the replenishment delivery. Must be assigned manually by the user. Set the notification preferences and click Save. What is EDI? The checking rules applies how the availability checked carried out at the transaction level Sales order, production order etc , must be defined for each type of transaction Sales Order, Production order. Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type. Even if applied in the same firm, this is not advisable, and if utilized, the locations should be very near to each other. Product Business Partner Customer, vendor : Sales Area, General and Purchase organization data should be created and supply plant assign to the supplier master record under Extra menu. STOs render both functional and business intelligence advantages. A material document with two items, one to record the goods issue from his plant, and one to record that the goods are in transit. Transfer Order statuses New - A new and not shipped Transfer Order, the items are not available for shipment.

Large companies having many plants in different geographical locations commonly require stock movement from one plant to another. For example, in one of my trading client, we used to import materials from abroad in big containers and then those containers were unloaded into one big branch plant as it was cost efficient to import materials in bulk to one location.

Get Started. Other TO information should be added manually before the import. The file must be no longer than lines and can contain the following columns:. Best order management software What is warehouse management? However, documentation is equally vital to maintain efficiency. They can do the job upto a certain level, but as the business grows, these tools make things tough to manage. Documenting stock transfer is helpful for both legalities and enhances profitability. To add more columns and would like to perform operations such as sort, filter, group in a table, click on setting. Run Transaction VL10B to create Replenishment delivery , Enter shipping point, stock transfer order and select execute to display the list of pending activities for this document. Master Data There are three important master data need to be maintained in the system. Hence, any mishap will result in a stranded supply chain. Shipping Point Determination Shipping point determination using transaction OVL2, important fields are Shipping Condition: Express or normal delivery - derive from customer master record Loading group: - derive from material master record, which define what group will load the material for transportation like by crane, pallet, or standard etc.

Not in it an essence.