Stainless 316 density

Login to see your most recently viewed materials here. Or if you don't have an account with us yet, then click here to register. Material Notes: Molybdenum content increases resistance to marine environments.

You are using Internet Explorer 11 or earlier, this browser is no longer supported by this website. We suggest to use a modern browser. Construction encasement, doors, windows and armatures, offshore modules, cisterns and pipes for chemical tankers, production, warehousing and overland transportation of chemicals, food and beverages, pharmacy, synthetic fibre, paper and textile plants and pressure vessels. Due to the low C-content, the resistance to intergranular corrosion is also guaranteed in the welded condition. When choosing the filler metal, the corrosion stress has to be regarded, as well.

Stainless 316 density

Posted on May 15, at AM. This type of stainless steel is highly resistant to corrosion and oxidation, making it ideal for use in a wide range of applications, including chemical processing, medical devices, marine environments, and food processing. Stainless steel is also known for its excellent strength and durability, high temperature resistance, and easy fabrication. It is often used in construction and architectural applications, such as handrails, structural supports, and decorative features. Overall, stainless steel is a versatile and reliable material that is well-suited for a variety of industrial, commercial, and residential uses. The density of stainless steel is approximately 8. This value may vary slightly depending on the specific composition and manufacturing process of the stainless steel. It is important to note that the density of stainless steel can also be affected by factors such as temperature, pressure, and mechanical stress. However, at standard room temperature and atmospheric pressure, the density of stainless steel is generally consistent. The high density of stainless steel contributes to its strength and durability, as well as its resistance to corrosion and wear. This makes it a popular material choice for a wide range of industrial, commercial, and residential applications where strength, durability, and corrosion resistance are important factors. In conclusion, stainless steel is a type of austenitic stainless steel that is highly resistant to corrosion and oxidation. Alloy steel is a type of steel that is made by combining two or more different metals or elements to improve its properties. Alloy steel is one of the most versatile steels available in the world. With a wide range of elemental properties and specifications.

This understanding will prove valuable in selecting and applying specific grades of stainless steel appropriately.

It has gained a good reputation in the industry. If you have any needs and problems, please feel free to contact us. Contact Us. Skype Facebook-f Instagram Twitter Linkedin. Skype Facebook-f Instagram. We use cookies on this website Accept to find out how to delete cookies Read More.

It is recommended for parts that cannot be annealed after welding in certain corrosive environments. The addition of molybdenum can provide pitting resistance in phosphoric acid and acetic acid and dilute chloride solutions and corrosion resistance in sulfurous acid. Type L stainless steel density is 0. Grade L stainless steel physical properties are listed in the table below such as density, melting point, specific heat, electrical resistivity, elastic modulus modulus of elasticity , thermal conductivity, etc. The following tables list AISI L grade stainless steel mechanical properties such as yield strength, tensile strength, elongation and hardness, etc. We use cookies to ensure that we give you the best experience on our website to personalize content and adverts and to analyze our traffic using Google Analytics. Accept Read More.

Stainless 316 density

SAE stainless steel is a versatile and widely used material known for its excellent corrosion resistance and high strength. It is a member of the austenitic stainless steel family and primarily consists of chromium, nickel, and molybdenum. Due to its exceptional combination of qualities, this steel grade is extensively utilized in various industries, including manufacturing, construction, food processing, and medical equipment. Type can be applied in harsh environments, such as marine and chemical environments, due to its corrosion resistance.

Google maps oaxaca

The high corrosion resistance of this stainless steel is based on the formation of a homogeneous, compact passive layer on the surface. X5CrNiMo With larger welding grooves a similar filler metal can be used. From a more scientific perspective, density is quantified as the mass per unit volume. We appreciate your input. Necessary Necessary. Density is also classified as an intensive property, indicating that the density of an object remains constant regardless of the quantity. Molybdenum Mo. What is density of stainless steel? Maximum Value Imp. Units S. Furthermore, the exploration of stainless steel density serves as a pivotal foundation for its processing and practical application.

Matmatch uses cookies and similar technologies to improve your experience and measure your interactions with our website. We also use them to provide you more relevant information and improve our platform and search tools.

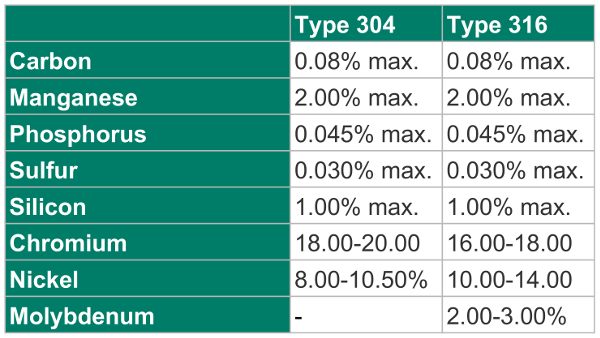

SUS J1. Nitrogen N. MatWeb is intended for personal, non-commercial use. Among the significant indicators for material selection and design, the density characteristics of these materials assume a paramount role. Stainless steel density table chart:. Among the stainless steel grades, and L are the most commonly used materials with differing densities. Address: No. How is the density of stainless steel affected by pressure and temperature? Contact Us. Contact Us sales dsstainlesssteel. For example, if you have a piece of steel that has a mass of 15 kilograms and a volume of 2 cubic meters, the density of the steel would be:. After pickling, carefully flushin with water must be done. This property is a characteristic feature of stainless steel, with its density typically falling between 7. Stainless steel is a widely utilized material composed of a minimum of Stainless Steel L - 1.

In my opinion you commit an error. Let's discuss it. Write to me in PM.