Seal weld symbol

We have received your request and will respond promptly. Log In. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.

Material Welding. Seal welds is a type of weld joint placement that provides an air-tight and water-tight connection for pipes or any other weld configuration. Seal welds are a specific type of welding commonly used in a variety of industries, such as construction, manufacturing and automotive repair. Seal welds are often employed in the production of products which require a high level of sealing integrity and strength. In this article, we will examine what seal welds are, how they work, and the benefits offered by using them. A seal weld is a type of weld that is intended to create a hermetic seal between two components or surfaces. As per the AWS A3.

Seal weld symbol

Powered by mwForum 2. Not logged in American Welding Society Forum. By zieglejo Date Could someone help me settle a "discussion" between my engineer and welders? The problem: a joint between two plates at approximately 90 degrees to each other; the inside corners of the plates are touching corner-to-corner; no overlap ; the weld takes place from the outside with complete penetration. The two questions are: Is it proper to put a "melt-thru" symbol on a fillet weld? Is this actually considered a fillet weld, or is it a 90 degree included angle, single-v-groove weld? I looked through AWS A2. Any comentary will be greatly appreciated. Thank you. By Date By jrw Date Good point Al. This probably is not the most structuraly sound joint detail, but in the few times I have seen it used it is generaly accompanied by two butt or v-groove welds and a fillet at a minimun, that would complete the welding of a joint.

It's not cut and dry is it? Interesting, I'd like to see pictures. A seal weld is a type of weld that is intended to create a hermetic seal between two components or surfaces.

What is a Seal Weld? A seal weld refers to a specific type of weld that is applied to create a seal or closure between two surfaces. It is commonly used to prevent the leakage …. Published on: 19 October It is commonly used to prevent the leakage or ingress of fluids, gases, or other substances in various industrial applications. The primary purpose of a seal weld is to provide a tight, secure, and impermeable joint.

What is a Seal Weld? A seal weld refers to a specific type of weld that is applied to create a seal or closure between two surfaces. It is commonly used to prevent the leakage …. Published on: 19 October It is commonly used to prevent the leakage or ingress of fluids, gases, or other substances in various industrial applications. The primary purpose of a seal weld is to provide a tight, secure, and impermeable joint. Seal welds are typically applied along the entire length or perimeter of a joint, ensuring complete sealing between the surfaces.

Seal weld symbol

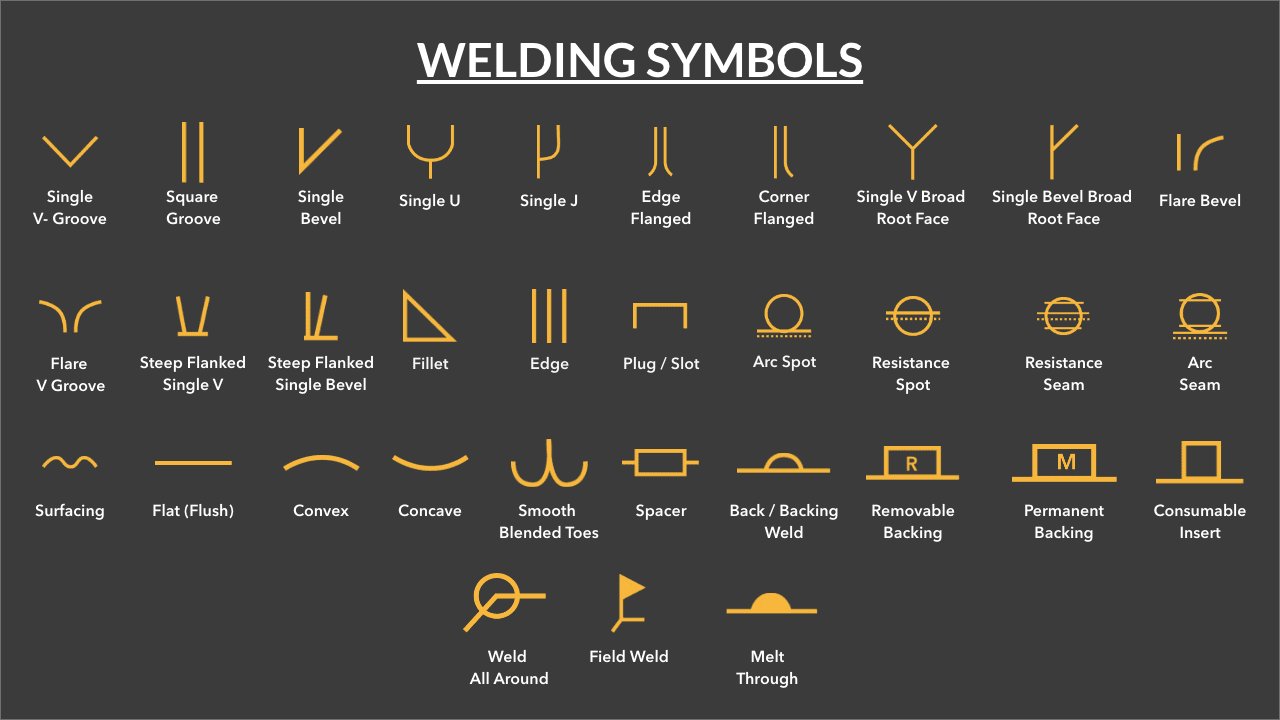

Material Welding. The welding symbol is a graphical representation that is used to give the design requirements to the shop in a concise manner. For E. The terms welding symbol and weld symbol have different meanings. A weld symbol indicates the required type of weld Sqaure, bevel, V, or fillet for example as shown in the below picture. These are called primary weld symbols.

Anime mouse pad

Hello Jeff; Your decision to join the ranks of our "trade" will serve you well over your working lifetime if you continue to learn and prefect your skills. Material Welding. This joint allows for neither, it has to be just right and is difficult to fit with out the aid of lugs, clips, etc. The edge weld depicted is used to "fuse" the edge joint, but if you look at the flanged edge, it forms an edge joint in that the two members meet tangent to each other and the dihedral angle between them is zero degrees. For that purpose it is a fine joint to practice on, but from a weld design, it is a poor detail. Similarly, if a groove weld is used for sealing, the symbol would reflect the specific type of groove weld for example, a square groove weld, V-groove weld, etc. RE: Weld symbol clarification for "seal" weld Nope. I stated before it is a poor weld detail and I still believe it is. Al, It looks like your right It is important to note that the tube hole in the tubesheet does not require beveling for a seal weld. This joint detail does require extra care on the welder's part to make the weld successfully.

Excellent Detailed Insights. Have you ever paused to wonder how massive storage tanks, high-pressure pipelines, and various industrial equipment stay leak-free, even under the harshest conditions? Seal welding plays a pivotal role in various industries, ensuring that connections remain air-tight and water-tight.

I stated before it is a poor weld detail and I still believe it is. Thanks for the compliments gentlemen. Reasons such as off-topic, duplicates, flames, illegal, vulgar, or students posting their homework. I also would say that it is a good way to work on puddle control and burnthrough, as I know first hand that even in the best fit up,k that outside corner takes skill to weld out correctly. I would have to look back through the records but i know the tube steel was just standard carbon steel typical of almost all our tube steel and i would have to dig out the spec for the wire but it the same stuff we use on all our handrail interior or exterior and we have never had a problem with: "since the welds were not sealed and air was allowed to get into the tube steel and condense forming water inside the tube, it is our opinion that corrosion on the inside of the tube steel is forming a large deposit of rust powder. In my opinion, melt thru is not the same thing as complete penetration. I have done this with weld with CJP many times. Seal welds are typically applied along the entire length or perimeter of a joint, ensuring complete sealing between the surfaces. Respectfully, Jeffrey. Seal welds are not guaranteed any strength.

It not so.

Excuse, it is removed