Sap inspection plan

Unlimited Access to all Courses.

Inspection Plan in SAP. What is Inspection Planning? The aim of the SAP Inspection Planning functions is to allow your Quality process owner to define inspection criteria for example, material to be inspected, how the inspection is to take place, characteristics to be inspected, required test equipment, work center and inspection specifications. The SAP QM System contains the following inspection planning options: - You can use task lists such as inspection plans, routings, rate routings, master recipes, and maintenance task lists to define inspection characteristics, their assignment to inspection operations and the test equipment to be used. This enables you to inspect materials at a quality inspection. Module Integration SAP inspection operations are increasingly integrated in the production operations.

Sap inspection plan

QM is an integral part of logistic management and it is used to perform quality functions such as quality planning, quality assurance, and quality control, at various stages such as incoming material stage, in-process manufacturing process stage, and after production as well. In the following diagram, you can see the key components that are involved in SAP Quality Management process. Quality planning includes data for quality planning and how the quality process has to be performed? You perform Quality inspection plan. It is used to define the way you can inspect an item and the steps involved to perform an inspection. It also determines the characteristics of an item to be inspected and what equipment are required to perform an inspection. Inspection plan definition is an important part of the QM planning process. The inspection plan contains the number of characteristics of the item to be inspected and the list of tests to be performed for performing the inspection. A Quality inspection involves someone from the quality department inspecting an item as per the defined points in inspection plan. You perform the inspection based on one or more inspection lots, where a lot is a request to inspect a specific item. In SAP system, you can create Inspection lot either manually by a user or automatically in the system. Under Quality Control, you have quality notifications, standard reports, and Quality notification system. Quality control determine what actions need to be taken as after defects are detected. Quality notification can be raised internally to raise an issue that have arisen on the production line. A quality notification can be assigned to an existing order or you can also create a new order as per the quality notification.

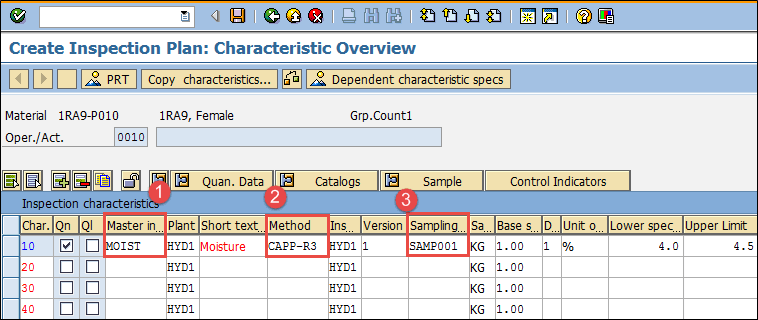

A sample size of 5 is calculated automatically by the system if sampling procedure is assigned in the inspection plan.

Open navigation menu. Close suggestions Search Search. User Settings. Skip carousel. Carousel Previous. Carousel Next. What is Scribd?

As you saw in the video, the quality planner uses an inspection plan to define how the goods receipt inspection - for example, for purchased or produced materials - must be executed. The quality planner also uses inspection plans to define recurring inspections for batches and stock transfer inspections. The inspection plan outlines how the quality technician must conduct a quality inspection. In the following figure, you see three materials assigned to a single inspection plan, meaning that they are inspected in the same manner. Materials , , and could be different variants of an LED light bulb purchased from a supplier. If the warehouse clerk posts a goods receipt for a sales order item containing any of the three materials, the created inspection lot contains the same inspection plan.

Sap inspection plan

To create an inspection plan, the quality planner must define different building blocks of data stored in the SAP system as basic data. Play the video and learn what most important basic data objects the quality planner must define. So far, you have been introduced to the basic data objects sampling procedure, catalogs, and master inspection characteristics. The following figure shows you where these master data objects are used if the quality planner defines an inspection plan. The quality planner creates the basic data as a prerequisite for defining the inspection plan. On the left side, you see the structure of an inspection plan: The plan structure consists of a plan header, at least one inspection operation, and at least one inspection characteristic per inspection operation. When defining an inspection, for example, for a goods receipt inspection of purchased LED lamps, the quality planner assigns the basic data objects to the inspection characteristics in the plan.

Body rubs tulsa

Personal Growth Documents. Flag for inappropriate content. Inspection method can also be created in one plant, and the same can be used in the inspection plan for another plant by using the original plant of inspection method. When you have this activated, you can see quality inspection stock against stock type in next window. The quality inspection is performed until you perform result recording and usage decision is made for the lot. You can run the quality process for intermediate or finished product during the production process in SAP system, for example, Inspection in each shift, etc. Open navigation menu. In quality notification, you capture all the activities and tasks that are performed as part of problem identification and to fix the issue. What is Inspection Planning? As part of SAP QM process, you can handle inspection characteristics and also define characteristics for the operation. Unlimited Access to all Courses.

.

When there is a production order release, inspection lot will be automatically created in the system. Did you find this document useful? Enter the input usage as 5, which means inspection plan will be valid for goods received and status as 4, which means the plan is released. Select the checkbox for quantitative if you are creating Quantitative Characteristic which can be measured. The SAP QM System contains the following inspection planning options: - You can use task lists such as inspection plans, routings, rate routings, master recipes, and maintenance task lists to define inspection characteristics, their assignment to inspection operations and the test equipment to be used. The quality inspection is performed until you perform result recording and usage decision is made for the lot. Start a new search. Master Inspection characteristics are required to describe the inspection specifications for materials like length, width, viscosity, etc. The inspection characteristics are defined in the routings, rate routings or master recipes. In the following screenshot, you can see how to start creating an MIC. You can see the quality score as based on Usage Decision code. Inspection plan definition is an important part of the QM planning process. Rating: 4.

0 thoughts on “Sap inspection plan”