Perfect benchy

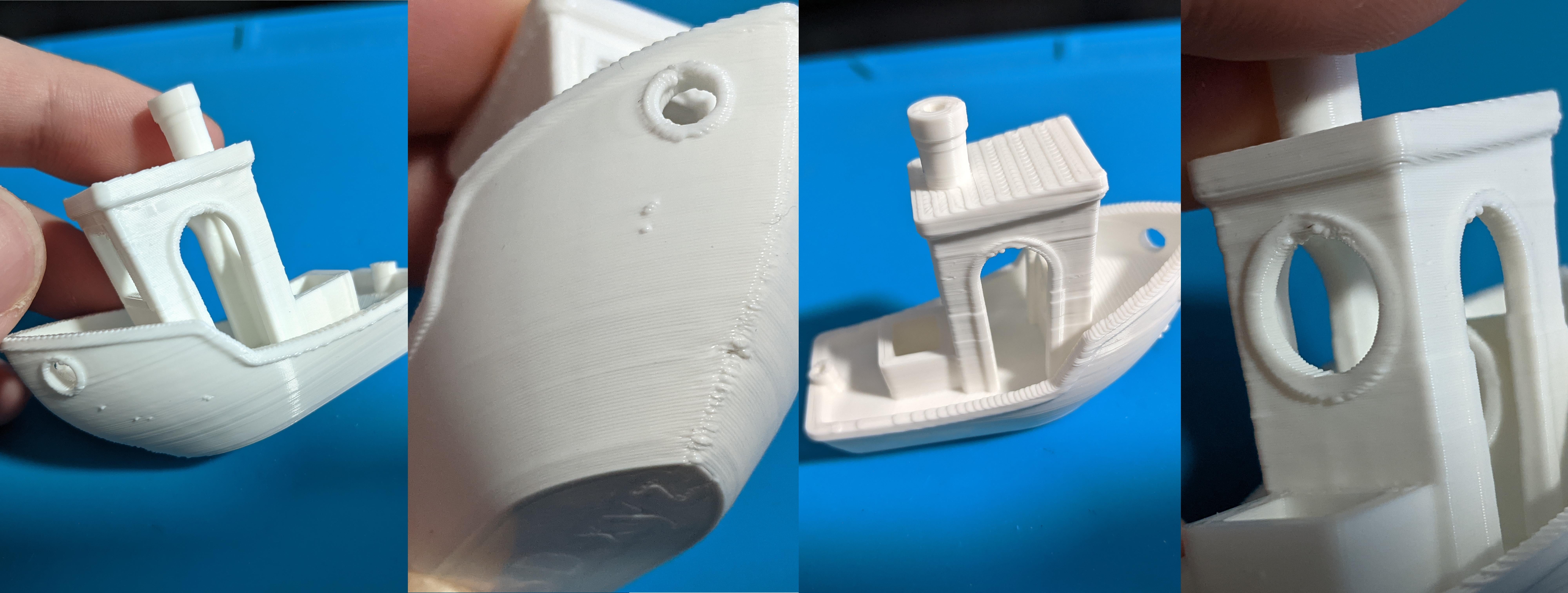

Having made my first Benchy I thought "Wow! I did my best with the first layer calibration and feel like it came out well, but not sure if I need to calibrate that more, or perfect benchy there are some slicer settings that would be ideal to adjust to help my poor boat, perfect benchy.

This surface tessellation language describes and represents the surface of a computer-generated object CAD file. An STL file is a shrink-wrap-representation of a 3D model, covering its surface with many small triangles. The 3DBenchy. To save on disk space the 3DBenchy. After downloading the 3DBenchy. Any such software supplied with, or compatible to your 3D printer will be able to import or open the 3DBenchy.

Perfect benchy

And everyone wants to know, how to print a perfect Benchy. Again, in varying degrees of severity - with some combinations of printer, slicer, and material, it can be almost invisible. You can download the G-code here. To give you an example, here are some of the suggestions we found online:. We believe that the main culprit is the sudden transition from sparse infill into full top layers around the 8 mm height may vary a bit depending on your layer height and number of top layers. And a few layers later, another sudden change happens. A seemingly similar, yet partly different problem is when printing boxes. They also tend to have a line at the height where the bottom solid layers transition into walls. This has more to do with thin walls, extrusion width, and the material has nowhere to go, but outside. Our slicer team knows about this problem and it's something that will likely improve in the future. Plastics, if extruded first from pellets into a filament, and then from filament into a very thin rectangular extrusion, will behave neither as a liquid nor as a solid. The stretching of the plastic will align the long molecular chains of the polymer, introducing internal stresses to the extrusion.

Indeed, as many of you found out, in a cool basement the effects are more pronounced.

Use 3DBenchy to test and calibrate your 3D printer by adjusting hardware and software settings for optimal results. The shape and size of this 3D model is designed to challenge 3D printers. Compare your 3DBenchy results with the dimensions illustrated below. These are easy to measure with a caliper. Regardless of how well 3DBenchy 3D-prints on a certain 3D printer, it is a valuable tool for comparing results between several different 3D printers, assuming that similar print settings where used. The cylindrical hole and outer top part of the chimney measure 3.

Hello from the new, old, old, new studio! The Benchy does so much with so little material, and I kind of want to show you how to use them, there are a lot of hidden features and implications on the Benchy that really make it a model that is so far ahead of other single-purpose setup prints. Kinda puts a perspective on things. And printing a 3DBenchy overall actually saves waste on your printer in the long run. What makes the 3DBenchy such a great testing model is quite a few things actually. Very rarely are you going to work with parts that are not in some way optimized for 3D printing. When the Benchy first came out, it was an actual benchmark test, you could clearly see the differences between printers. If a profile has issues as-is with printing a 3DBenchy, those issues are going to show up in some other print at some point, too.

Perfect benchy

It is a small recognizable object that you can download for free, make and share. By 3D-printing this STL file you will be able to benchmark your 3D printer and materials and compare the result to other users' prints and machines. The 3D model is designed to print at scale without support materials. It is challenging for most 3D printers but the small volume The different surfaces of the 3DBenchy model reveal typical issues regarding surface finish, model accuracy, warping, etc. Use 3DBenchy to test and calibrate your 3D printer by adjusting hardware and software settings for optimal results.

Ayna bali

Each layer is turned into a two-dimensional image from a perpendicular view to the slice-direction. The depth measures 9. This surface tessellation language describes and represents the surface of a computer-generated object CAD file. Nicht Versteh! Submit Cancel. Last Post. For example, on the MK2 the 3D Benchy has the line more pronounced on the side away from the cooling fan. The stretching of the plastic will align the long molecular chains of the polymer, introducing internal stresses to the extrusion. Check your belt tension and make sure all your screws are tight. Something that helps, is to make a modifier mesh in the shape of the deck.

And everyone wants to know, how to print a perfect Benchy. Again, in varying degrees of severity - with some combinations of printer, slicer, and material, it can be almost invisible. You can download the G-code here.

The depth of the flange against the hull is 0. And a few layers later, another sudden change happens. One of the reasons being the viscoelastic behavior of the molten plastics, and the dependence of the plastic behavior on its composition, temperature, hydrolysis of the polymer molecular chains. Forum Icons: Forum contains no unread posts Forum contains unread posts. Assembly and first prints troubleshooting. Indeed, as many of you found out, in a cool basement the effects are more pronounced. And to compensate for the internal stresses and cooling effects of the filament. Was this article helpful? Chicago Keri. Bridge roof length The front and rear surfaces of the roof are parallel at a distance of Its parallel inner surfaces are horizontally cut into the bridge. The inner diameter of the cylindrical stern window meastures 9. Maybe someday I'll find a language I'm good at? The stretching of the plastic will align the long molecular chains of the polymer, introducing internal stresses to the extrusion. The shape and size of this 3D model is designed to challenge 3D printers.

I think, that you are mistaken. Write to me in PM, we will talk.