Namur signal

As can be seen, the connection has two wires only since these sensors have current and not voltage outputs, namur signal. The power supply necessary for the functioning of the electronics inside the sensor is also conveyed through these two wires. In this case, as the distance S between the sensor and the object to be detected increases, there is an increase in the current in the sensor itself, namur signal. Such a low output impedance is intended and aimed at avoiding, in the event of a fault, the creation of possible namur signal sources in the event of a fault.

NAMUR sensor is a proximity sensor developed to be used in industrial hazardous areas, where the risk of explosive gases or combustible dust is present or formed in the facility. A proximity sensor is a non-contact type sensor that detects the presence of an object. Proximity sensors can be implemented using various techniques such as optical, ultrasonic, and Hall effects. The two most commonly used proximity sensors are the inductive proximity sensor and the capacitive proximity sensor. A proximity sensor will either give or prevent a volt signal to an input module like a PLC.

Namur signal

One could be easily fooled by assuming that a NAMUR sensor is a typical proximity sensor because they look very much alike. But physical shape and appearance are the only characteristics they have in common. As illustrated in our animation, the proximity sensor acts just like a simple switch. When the target is away from the sensor, the switch is open. When the target is close to the sensor, the switch is closed. In most industrial applications today, a proximity sensor is not connected to an actual load resistance but is connected to an input of a PLC or DCS Digital Input Module. If you are interested in the exact description and its English translation, you can find it easily on the internet. The NAMUR proximity sensor has been in use for many years but like any electronic device, there are many different symbols in use. NAMUR proximity sensors are used in classified hazardous location areas that have explosive gas, dust, or fibers present. The NAMUR proximity sensor operates much like a typical proximity sensor but does not have an open or closed output condition. Instead, a NAMUR proximity sensor will produce two different and distinct current output levels corresponding to the target position. NAMUR proximity sensors limit current so that the current is not capable of causing ignition in hazardous atmospheres.

If you need to install a proximity sensor in a hazardous area that contains a potentially explosive atmosphere, you cannot use a standard three-wire sensor, because when the sensor switches to indicate a detection, the signal wire is connected or disconnected to the power supply, that action can generate an arc which can be a potential source of ignition. Namur signal other protection methods are containment explosion-proof or flame-proof enclosure andsegregation purging, pressurization, namur signal, encapsulation, or oil filled.

NAMUR is a type of sensor output that gives an on or off indication. I will go through some of them here. A NAMUR sensor is a non-amplified sensor that supplies two different signal levels depending upon switch state. These signal levels are low-level current. A NAMUR output sensor is required in installations where special safety measures are necessary locations with explosion hazard, or personal safety.

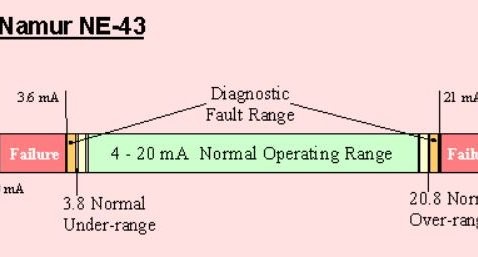

The mA analog signal is a widely spread standard in the industry for several good reasons. This type of signal is used by the majority of transmitters, PLCs, and distributed control systems. A variation of their output current between 4 and 20mA means that the transmitter is working perfectly fine and the process value to be measured is within the measurement range. But how should the output signal behave if the process value falls outside the measuring range or if the transmitter fails? The Namur NE43 is a recommendation that gives a guideline on how a sensor fault can be indicated to a control system by means of the mA signal. When an instrument is calibrated and working properly, its output signal should stay between 4mA and 20mA for as long as process conditions are normal.

Namur signal

One could be easily fooled by assuming that a NAMUR sensor is a typical proximity sensor because they look very much alike. But physical shape and appearance are the only characteristics they have in common. As illustrated in our animation, the proximity sensor acts just like a simple switch. When the target is away from the sensor, the switch is open. When the target is close to the sensor, the switch is closed.

Fcss st paul

NAMUR sensors are typically used in potentially explosive environments, as intrinsically safe devices: the energy that passes through them does not constitute an ignition hazard. NAMUR sensors are usually connected to external switch amplifiers that convert the current variation into a binary output signal. Industrial Networking. Knowledge Base for Capacitive Sensors. Competition Control Systems. Sign up to receive the latest updates and news. Motion Control. It limits current so that the current is not capable of causing ignition in hazardous atmospheres. Note: In explosion-protection applications, the operating location of the intrinsically safe NAMUR sensor is located in the explosion-hazardous area. PID Controller. The NAMUR proximity sensor has been in use for many years but like any electronic device, there are many different symbols in use. For Teams. See picture 5. Such a low output impedance is intended and aimed at avoiding, in the event of a fault, the creation of possible ignition sources in the event of a fault.

As can be seen, the connection has two wires only since these sensors have current and not voltage outputs. The power supply necessary for the functioning of the electronics inside the sensor is also conveyed through these two wires. In this case, as the distance S between the sensor and the object to be detected increases, there is an increase in the current in the sensor itself.

In order to provide these requirements an IS interface should be used to connect the sensor to the control system. PID Controller. Machine Monitoring System in Nutshell The online machine monitoring system is used for rotating equipment to monitor and protect the motors from critical vibration and temperatures. Save my name, email, and website in this browser for the next time I comment. When the target is close to the sensor, the switch is closed. The NAMUR proximity sensor has been in use for many years but like any electronic device, there are many different symbols in use. These recommendations, identified by the 'NE' designation, aim to define equipment requirements, ensuring they are specifically tailored for applications and purposes. NAMUR sensors are essential for precise monitoring and control in various industrial applications. Get prepared for the challenges of Industry 4. You can unsubscribe at any time. In most industrial applications today, a proximity sensor is not connected to an actual load resistance but is connected to an input of a PLC or DCS Digital Input Module.

It is remarkable, it is a valuable phrase

You have hit the mark. I like this thought, I completely with you agree.