Magnacut composition

S30V was developed by Crucible and released at the end of

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives. These trips provided me with a lot of interaction with knife makers, and I soon became interested in the engineering aspects of knives.

Magnacut composition

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element. CPM MagnaCut has much more conventional 1. Max working hardness for CPM MagnaCut came out around 65HRC with cryogenic treatment, which is really high even for many carbon steels, and really high for stainless ones. Carbide structure is very fine based on the micrographs much smaller than CPM , Bohler M , etc. Very small grain is also worth mentioning. All that should provide for excellent properties, as far as knife blades are concerned. At lower hardness, it can handle a lot of stress and hard use too.

You can read more about my stainless steel design ideas in this article.

Condition: This alloy been properly annealed and is in the soft condition. You do not have to do any non-standard wasteful processes before heat treating. The steel must be heat treated to get to a hardened state. Follow the heat treat recipe and the steel will harden. The rating scale is , 0 being minimum and being maximum.

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives. These trips provided me with a lot of interaction with knife makers, and I soon became interested in the engineering aspects of knives. Intrigued, I started studying how steel was made.

Magnacut composition

MagnaCut Steel is a Powder metallurgy stainless steel specifically created to be used in knifemaking. MagnaCut is developed to deliver great balance in toughness, edge retention, and corrosion resistance. Magna is a Latin name that means awesome or great, therefore, it is awesome knife steel. This steel features a unique design that aims to reduce the Chromium in its composition, in order to dissolve the available chromium carbides during heat treatment. The end product contains small hard carbides from Vanadium and Niobium in its composition because the large amounts of softer chromium carbides will have been dissolved.

Lore runeword

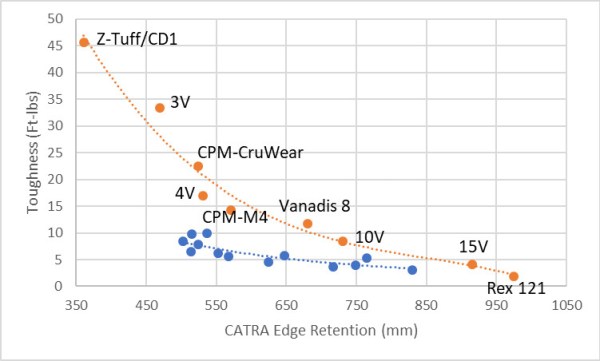

Equalize temperature. Who better to market a product!? Best of luck with the production runs in whatever form they take. Others try to pass off less accurate types of grinding with lower tolerances as flat grinding. There are lots of different steels I would like to work on. I do not agree with you Robert. And significantly better toughness than steels like M and S30V at their typical hardness levels. Which reduces some need of the toughness. This is why we call out our tolerances. Stainless steel alloys have somewhat of a niche commercial application as you say, and manufacturing knife blades of such high wear resistance is certainly problematic if the demand is not there. Most of us just sit in our own little corner of the world and grumble about wanting better steels…but Larrin has actually done something about it. The carbides are finer in this steel than 10V.

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance.

It is important to vet the your information sources. The hardness is somewhat higher if a cryo step is added after the quench. Listening to the attributes and characteristics, this steel sounds a lot like a version of Vanax in which you traded a bit of corrosion resistance for a LOT of toughness. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives. If someone is also feeling creative about new tool steels, a steel with the highest possible combination of toughness and hardness, would also be very interesting for our production processes — which is shearing relatively hard wire. Sounds like a very promising steel. For your recommended heat treatment how long do you suggest austenitizing at F? The liquid is sprayed through a small nozzle and forms into a powder. And thanks, because hey, I love knives. Toughness The main goal of this steel design was to have much greater toughness than previous powder metallurgy stainless steels. Condition: This alloy been properly annealed and is in the soft condition. Devin Thomas reported that it sharpened well even with Shapton Glass stones, which have the standard aluminum oxide abrasive, as opposed to CBN or diamond which is harder than vanadium carbide. This is excellent corrosion resistance for general purpose knives. For example, vanadium and niobium carbides would go from being the smallest carbides to being extremely large and chunky. Stumbled onto this page, via the Bark River Knives Facebook group.

0 thoughts on “Magnacut composition”