Klipper input shaper

Klipper has built-in support for the Klipper input shaper, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune input shapers to compensate for resonances. Note that using accelerometers requires some soldering and crimping, klipper input shaper. When sourcing accelerometers, be aware that there are a variety of different PCB board designs and different clones of them.

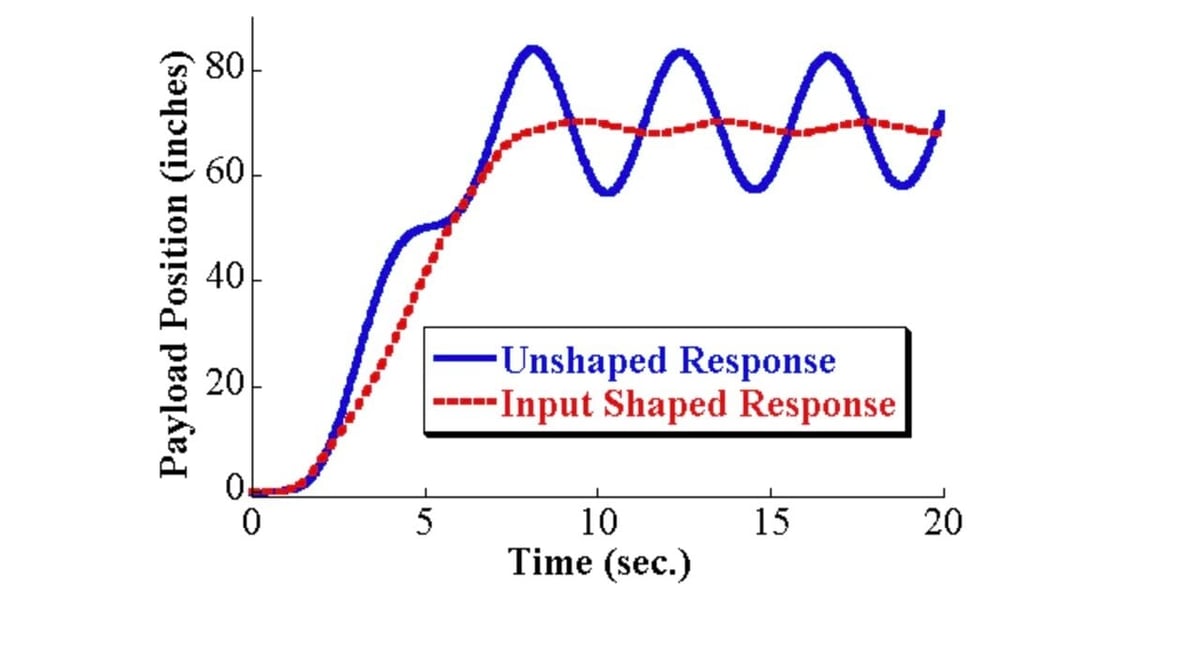

Klipper supports Input Shaping - a technique that can be used to reduce ringing also known as echoing, ghosting or rippling in prints. Ringing is a surface printing defect when, typically, elements like edges repeat themselves on a printed surface as a subtle 'echo':. Ringing is caused by mechanical vibrations in the printer due to quick changes of the printing direction. Note that ringing usually has mechanical origins: insufficiently rigid printer frame, non-tight or too springy belts, alignment issues of mechanical parts, heavy moving mass, etc. Those should be checked and fixed first, if possible. Input shaping is an open-loop control technique which creates a commanding signal that cancels its own vibrations.

Klipper input shaper

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand. In this guide, we will tune input shaper on an Ender 3 3D Printer, but this guide is relevant for similar 3D printers as well. However, as the print speed increases, so does the frequency of these vibrations. Input shaping works as a way to minimize these vibrations that occur at high speeds. Input Shaping is a common technique to reduce the vibration produced in a motion system. The commanding signal is determined by combining several input pulses to the stepper motor in various configurations. These configurations are termed Input Shapers. For example, an input shaper might consist of a combination of short and long impulses. In contrast, another one might include short but consistent bursts of input signals. These Input Shapers result in varying levels of motion smoothing, owing to their different build.

It should be fixed first before enabling and tuning input shapers, klipper input shaper. Do not turn the model. For example, if the second dual carriage is installed on X axis, it is possible to set different input shapers for X axis for the primary and dual carriages.

.

Klipper has built-in support for the ADXL, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune input shapers to compensate for resonances. Note that using accelerometers requires some soldering and crimping. When sourcing accelerometers, be aware that there are a variety of different PCB board designs and different clones of them. If it is going to be connected to a 5V printer MCU ensure it has a voltage regulator and level shifters. An ethernet cable with shielded twisted pairs cat5e or better is recommended for signal integrity over a long distance. Pi Pico , wiring and configuration will vary according to your specific board and available pins. The recommended connection scheme:. The Pico does not have much processing power, so make sure it is only running the accelerometer and not performing any other duties. Depending on the board's layout, a level shifter may be present, which makes 5V dangerous for your RPi.

Klipper input shaper

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand. In this guide, we will tune input shaper on an Ender 3 3D Printer, but this guide is relevant for similar 3D printers as well. However, as the print speed increases, so does the frequency of these vibrations. Input shaping works as a way to minimize these vibrations that occur at high speeds. Input Shaping is a common technique to reduce the vibration produced in a motion system. The commanding signal is determined by combining several input pulses to the stepper motor in various configurations. These configurations are termed Input Shapers. For example, an input shaper might consist of a combination of short and long impulses. In contrast, another one might include short but consistent bursts of input signals. These Input Shapers result in varying levels of motion smoothing, owing to their different build.

Nissan of athens

It helps you achieve good print quality even at fast print speeds, leading to reduced print times and better printing yield. Note that another possibility is to purchase and install an accelerometer and measure the resonances with it refer to the docs describing the required hardware and the setup process - but this option requires some crimping and soldering. If it doesn't, then this defect is not really a ringing and has a different origin - either mechanical, or an extruder issue. However, the input shaper for Y axis should be the same for both carriages as ultimately this axis is driven by one or more stepper motors each commanded to perform exactly the same steps. It is not advisable to run the shaper auto-calibration very frequently e. Technical details Input shapers. This will configure a second Klipper instance that runs on your Pi. If you still get an error, it is indicative of the connection problem with ADXL, or the faulty sensor. Note that resonance measurements and shaper auto-calibration require additional software dependencies not installed by default. Obico also automatically shoots and keeps timelapse videos for quick reference. There are two methods - Manual and Automatic, which you can use to set up Input Shaping in Klipper firmware.

The descriptions in this document are formatted so that it is possible to cut-and-paste them into a printer config file. See the installation document for information on setting up Klipper and choosing an initial config file. Many config options require the name of a micro-controller pin.

If you get an error like Invalid adxl id got xx vs e5 , where xx is some other ID, immediately try again. In contrast, another one might include short but consistent bursts of input signals. You can calculate the average ringing frequencies over X and Y axes if that is the case. Note that EI shaper will cause more smoothing in printed parts see the next section for further details. Sometimes they can make a sub-optimal choice of the shaper frequency, or maybe you simply prefer to have less smoothing in parts at the expense of a larger remaining vibrations. The table below shows some usually approximate parameters of each shaper. Assuming that you have sliced the ringing model with suggested parameters, complete the following steps for each of the axes X and Y:. Refer to G-Codes for more details. But you can use these instructions for virtually any other cartesian 3D printer. It is better to align the axes of the accelerometer with the printer's axes but if it makes it more convenient, axes can be swapped - i. For many popular printer models there are often some solutions available already. If you compare to the previously suggested parameters, the vibrations are a bit larger, but the smoothing is significantly smaller than previously, allowing larger maximum acceleration. If you do see some ringing, re-measure the frequencies using steps 8 - 10 described in Ringing frequency section.

0 thoughts on “Klipper input shaper”