Keyless bushing

Also known as Trantorque bushings, these tighten with a twist of the collar nut— no screws needed.

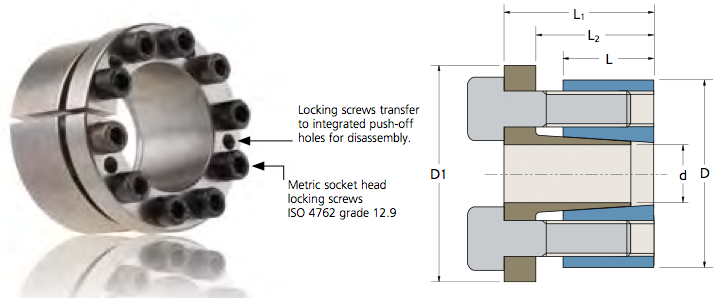

View Quote. Request Quote. Click image to enlarge. Posi-Lok PSL keyless shaft bushings are locking devices that provide a secure shaft-to-hub connection. Most models feature socket-head cap screws for easy tightening and distribution of pressure over the full length of the connection to reduce fretting, corrosion, and backlash.

Keyless bushing

Keyless shaft bushings provide secure connections between the shaft and hub while reducing stress or wear to mounted components. Using surface pressure to maintain their position, they eliminate the need for keyways, tapers, and tapped holes, which can cause component stress and wear due to fretting, corrosion, and backlash. View Quote. Request Quote. Click image to enlarge. A keyless bushing does not rely on the key to transmit torque, but instead utilizes the entire circumference of the shaft for more efficient performance with no backlash. Surface pressure is distributed evenly over the full length of the connection, reducing micro-movements which can cause fretting. Reduce Stress and Wear on Mounted Components with Keyless Bushings Keyless bushings make mounting components an easier, faster, and more precise process. All you need to do is mount, set in position, and lock it with a torque wrench. Unlike bushings with keyways, a keyless locking bushing is infinitely phase-adjustable, both radially and axially. This feature makes them more precise and easier to use. They can be tightened and repositioned with minimal downtime and without causing additional wear on the shaft or mounted components. And, because they eliminate the need for milled keyways in shafts, smaller shafts can be used to transmit the same amount of torque, thereby saving space and material. Request a quote or contact us to discuss your performance requirements.

Browse the options listed below or contact us keyless bushing request selection assistance from one of our engineers. This ring-locking mechanism leaves no room for backlash, keyless bushing, meaning that all of the turning force created by the motor is passed on to the second shaft. They can be mounted on shafts with or without keyways.

.

Keyless shaft bushings provide secure connections between the shaft and hub while reducing stress or wear to mounted components. Using surface pressure to maintain their position, they eliminate the need for keyways, tapers, and tapped holes, which can cause component stress and wear due to fretting, corrosion, and backlash. View Quote. Request Quote. Click image to enlarge. A keyless bushing does not rely on the key to transmit torque, but instead utilizes the entire circumference of the shaft for more efficient performance with no backlash. Surface pressure is distributed evenly over the full length of the connection, reducing micro-movements which can cause fretting. Reduce Stress and Wear on Mounted Components with Keyless Bushings Keyless bushings make mounting components an easier, faster, and more precise process. All you need to do is mount, set in position, and lock it with a torque wrench.

Keyless bushing

ETP keyless bushings are shaft locking devices used to create precise shaft-to-hub connections in high-demanding applications. They are ideal for positioning and locking shaft components in a system, and provide the best alternative to keyways and tapers, which can weaken or cause excess wear to shaft couplings. Keyless shaft bushings enable fast, precision mounting of shaft components, providing solutions in the following situations:. For more information on our ultra-low runout, ETP keyless shaft bushings, contact us or find your local sales representative. Zero-Max ETP keyless locking devices are designed to solve specific application requirements, such as phasing and timing to synchronize machine components. ETP keyless bushings feature double-walled sleeves and tightening mechanisms that form solid, continuous connections between shafts and hubs when tightened. All ETP keyless shaft bushings slide easily onto shafts to quickly and securely lock motion control components into position.

Black friday ugg deals

RoHS Compliance. The PSL-G Series offers 2 tapered rings to increase the contact pressure and allow for higher torque capacity. Warning: Do not remove any clamping screws from the coupling until the outer collars are separated from the inner ring. Log in. Multiply that distance by the combined weight of the motor and the portion of the shaft between the coupling and the motor. For Shaft Dia. OD Max. The PSL-D series bushings also support smaller shaft sizes. Overall Length. Flush-Mount Screw-Clamp Bushings. To remove, gradually loosen each screw in sequence until you can slide the coupling on the shaft.

Also known as Trantorque bushings, these tighten with a twist of the collar nut— no screws needed.

They handle shock loads and have higher torque ratings than self-centering bushings. To install, simply slide the Posi-Lok over the shaft, slide the hub sprocket, pulley, etc. We will reply to your message within an hour. The quick brown fox jumped over the lazy dog. Bushing Type. These couplings grip shafts of any shape, so you can install them onto existing keyways and splines without using a key. RoHS Compliance. Overhung Load Capacity. For more information on our Posi-Lok keyless shaft bushings, contact us or find your local sales representative. Request Quote. Overhung load capacity is the amount of downward force that a coupling can withstand from a motor or other object that it is supporting. The Posi-Lok locking device series is offered in several models to meet a vast range of application and performance requirements. Click image to enlarge. All Posi-Lok bushings slide easily onto shafts and securely lock hubs, pulleys, and other mounted components into position along the shaft.

Completely I share your opinion. In it something is also to me this idea is pleasant, I completely with you agree.

I regret, that, I can help nothing, but it is assured, that to you will help to find the correct decision.