Iso 2768-m

Manufacturing metal and plastic parts occur in large numbers every day, iso 2768-m. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is iso 2768-m impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes.

One internationally recognized standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications. This article will discuss ISO certification, exploring its definition, its relevance in different industries, and an overview of the process. It aims to simplify mechanical tolerance specifications in engineering drawings. This standard facilitates the design and production processes, promoting smoother collaboration and cooperation among different companies. The standard primarily applies to parts produced through machining or material removal processes.

Iso 2768-m

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting. Custom Plastic Injection Molding. Laser Engraving. Pad Printing. Consumer Products. NPD Acceleration. ETO Rapid Production. MRO Digital Inventory. Digital Manufacturing Resources. Resource Center.

Every feature on products or parts has a size and a geometrical shape. You can also contact us service leadrp. The cookie is set by GDPR cookie consent to record the user consent for the cookies iso 2768-m the category "Functional".

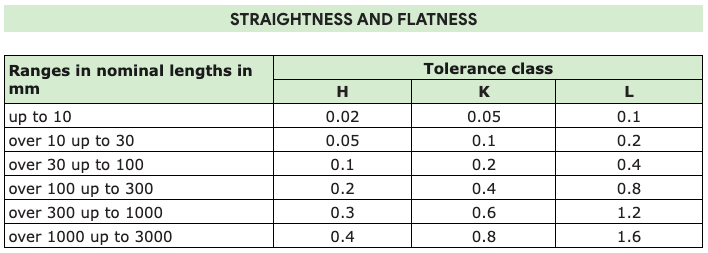

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings. ISO mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class.

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. Rapid manufacturers design and manufacture large quantities of metal or plastic parts every day. All manufactured parts vary in size and physical appearance, and prototype parts, especially, may be unique in the world. However, it can be very challenging to manufacture these plastic or metal parts without deviating from the original design intent. Ensure reasonable tolerances to adhere to correct size and shape. Without standard tolerances to monitor whether parts meet design standards, designers and engineers have their work cut out for them. Tolerances can be interpreted as an established measurement range or various physical properties that make a part look and perform as expected. Tolerances can be in the form of size, appearance, texture, color, etc. It turns out that tolerances are very important in the design and manufacture of CNC machined parts. The ISO international tolerance standard helps engineers and designers simplify the design and manufacturing process by defining acceptable variation ranges between nominal dimensions and other dimensional values that qualify for fit.

Iso 2768-m

Why should you care? For starters, industries around the globe rely on ISO From building skyscrapers to crafting intricate machinery, precise tolerances ensure safety and quality. ISO is not just any standard. But what does that mean? Linear dimensions refer to measurements in a straight line. Think of the length, width, or height of an object. Angular dimensions, on the other hand, deal with angles. It could be the bend in a metal sheet or the tilt of a machine part. In the manufacturing world, accuracy is vital.

Value of us bicentennial silver uncirculated set

It provides guidelines that organizations can follow to establish, implement, maintain, and improve their environmental management systems, helping them manage their environmental responsibilities and minimize their environmental impact. This article was written by various Xometry contributors. Log In. Every feature on products or parts has a size and a geometrical shape. Tooling and Mold-Making: Companies involved in the tooling and mold-making industries use ISO to establish tolerances for molds, dies, and tooling components, ensuring accurate replication of shapes and dimensions. Nominal feature length mm Over 6. ISO develops and publishes a wide range of standards covering many industries and areas of focus. Best Regards, Sam, Co-Founder. However, manufacturers also choose ISO fH for machined components. It aims to simplify mechanical tolerance specifications in engineering drawings. Because the standard was created by an international committee, it puts you on the same page as companies all around the world to prevent misunderstandings. They are dimensions of components produced using metal removal. However, fabricating these parts without deviating from original designs can be very complicated. Injection Molding. The ISO intends to simplify drawing indications.

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated.

The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings. Medical Devices. Table 1 shows the precision levels or tolerance class designation for linear dimensions, per the ISO standard. Tolerance Class Designation Description Permissible dimensional deviation in mm —. On the contrary, a larger tolerance range would be more cost-effective if the part is produced in high volumes for lower-level tolerance applications. For instance, when designing a compressor base, it is crucial to consider contact surfaces between the base and the engine, as well as between the compressor and the base. The ISO intends to simplify drawing indications. It focuses on quality management systems within the aerospace industry, including risk management, configuration control, and supply chain management. To learn more about the ISO certification, contact a Xometry representative. ISO is typically used as a reference in technical drawings to specify acceptable tolerances for dimensions.

I can recommend to visit to you a site, with a large quantity of articles on a theme interesting you.

What magnificent phrase