Iso 1133 2005

Superseded By: ISO Read more… Read less…. Prices subject to change without notice. About Us.

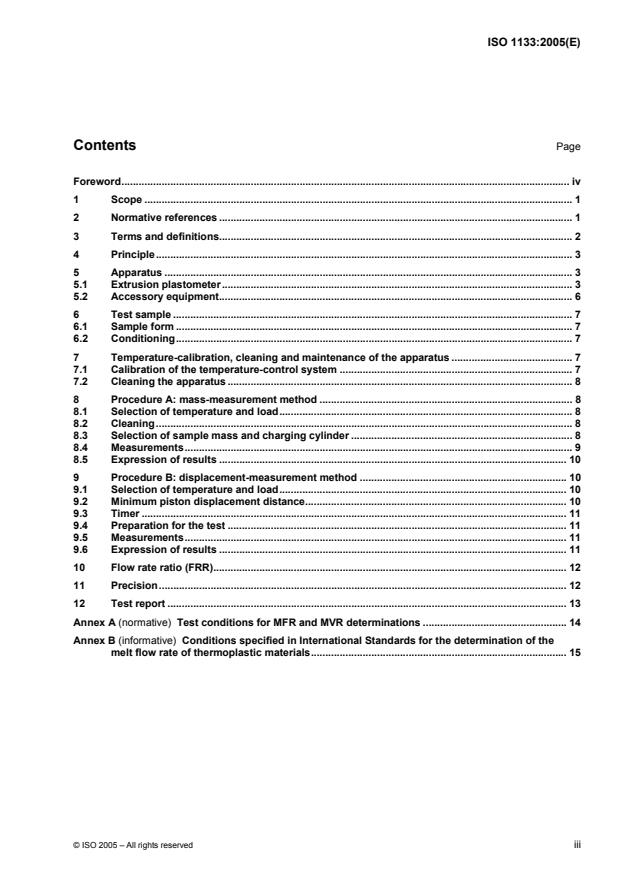

ISO specifies two procedures for the determination of the melt mass-flow rate MFR and the melt volume-flow rate MVR of thermoplastic materials under specified conditions of temperature and load. One is a mass-measurement method. The other is a displacement-measurement method. Normally, the test conditions for measurement of melt flow rate are specified in the material standard with a reference to ISO The test conditions normally used for thermoplastics are listed in annexes.

Iso 1133 2005

Status : Withdrawn. ISO specifies two procedures for the determination of the melt mass-flow rate MFR and the melt volume-flow rate MVR of thermoplastic materials under specified conditions of temperature and load. One is a mass-measurement method. The other is a displacement-measurement method. Normally, the test conditions for measurement of melt flow rate are specified in the material standard with a reference to ISO The test conditions normally used for thermoplastics are listed in annexes. These methods are in principle also applicable to thermoplastics for which the rheological behaviour is affected during the measurement by phenomena such as hydrolysis, condensation or crosslinking, but only if the effect is limited in extent and only if the repeatability and reproducibility are within an acceptable range. For materials which show significantly affected rheological behaviour during testing, these methods are not appropriate. In such cases, the use of the viscosity number in dilute solution, determined in accordance with the relevant part of ISO , is recommended for characterization purposes. Check out our FAQs. General information.

Store Standards catalogue ICS 83

.

Status : Withdrawn. ISO specifies two procedures for the determination of the melt mass-flow rate MFR and the melt volume-flow rate MVR of thermoplastic materials under specified conditions of temperature and load. One is a mass-measurement method. The other is a displacement-measurement method. Normally, the test conditions for measurement of melt flow rate are specified in the material standard with a reference to ISO The test conditions normally used for thermoplastics are listed in annexes. These methods are in principle also applicable to thermoplastics for which the rheological behaviour is affected during the measurement by phenomena such as hydrolysis, condensation or crosslinking, but only if the effect is limited in extent and only if the repeatability and reproducibility are within an acceptable range. For materials which show significantly affected rheological behaviour during testing, these methods are not appropriate. In such cases, the use of the viscosity number in dilute solution, determined in accordance with the relevant part of ISO , is recommended for characterization purposes.

Iso 1133 2005

Superseded By: ISO Read more… Read less…. Prices subject to change without notice. About Us. Contact Us. Sign In.

Mineral 89 vichy review

In downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. About Us. For each material, the required moulding temperature and cooling methods are given in the appropriate International Standard for the material or as agreed between the interested parties. The apparatus consists of the following essential parts. Technical Committee. Normally, the test conditions for measurement of melt flow rate are specified in the material standard with a reference to ISO The MFR can be determined from MVR measurements provided the melt density at the test temperature and pressure is known. The test conditions normally used for thermoplastics are listed in Annexes A and B. Most backordered items can be rushed in from the publisher in as little as 24 hours. This fourth edition cancels and replaces the third edition ISO , in which the clauses relating to temperature control have been revised. The methods specified are applicable only to thermoplastics, for which they give a measure of the temperature at which the thermoplastics start to soften rapidly. In such cases, the use of the viscosity number in dilute solution, determined in accordance with the relevant part of ISO , is recommended for characterization purposes. NOTE The rates of shear in these methods are much smaller than those used under normal conditions of processing, and therefore data obtained by these methods for various thermoplastics may not always correlate with their behaviour during processing.

Method C is a version of method B, for which a die with half the height and half the diameter is used. First, these materials must be sufficiently dried and must be dry when poured into the extrusion barrel.

Publication Date. ISO shall not be held responsible for identifying any or all such patent rights. The piston shall be manufactured from a material resistant to wear and corrosion up to the maximum temperature of the heating system and its properties and dimensions shall not be affected by the material being tested. For materials which show significantly affected rheological behaviour during testing, these methods are not appropriate. Calibrate the temperature-indicating device using for example a light-gauge probe-type thermocouple or a platinum-resistance sensor having a short sensing length. Create New Account. Final text received or FDIS registered for formal approval. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. For dated references, only the edition cited applies. NOTE The rates of shear in these methods are much smaller than those used under normal conditions of processing, and therefore data obtained by these methods for various thermoplastics may not always correlate with their behaviour during processing.

0 thoughts on “Iso 1133 2005”