Impact sockets vs chrome

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Outstanding Performance from a Global Leader. For more information click here.

Forums New posts Search forums. Media New media New comments Search media. Members Current visitors New profile posts Search profile posts. The Alliance. The Store. Log in Register. Search titles only.

Impact sockets vs chrome

Our mission is to empower mechanics to achieve more in everyday projects by providing them with accessible, high-quality tools and accessories that accompany them for a lifetime. What kind of socket are you working with today? Is it a chrome socket or an impact socket? Both socket types have their own set of advantages and specific use cases that will help you to get the job done right. What distinguishes impact sockets vs. Our professional set of impact sockets are forged from industrial-grade Chromium Molybdenum Cr-Mo steel for strength and shatter-resistance, making the tool capable of handling great torque as well as extreme shocks and vibrations delivered by impact guns. Cr-Mo is actually more malleable than Cr-V chrome sockets which helps contribute to their shatter-resistance. Impact sockets have the advantage of withstanding higher torque, with the tradeoff of being a bit thicker so they can withstand a lifetime of heavy use. Our chrome sockets are forged from Chromium Vanadium Cr-V steel and the heat treatment process is calibrated to give them very high hardness. The hardened material allows chrome sockets to be designed with very thin walls, which makes them perfect to use in narrow spaces when applying hand torque, making your job easier.

PWC Repair said:. January 20,

Here handtool manufacturer STE discusses the benefits and differences between impact socket sets and regular socket sets and how to identify which set is right for a particular application. More commonly, regular sockets are mostly chrome in colour and impact sockets are mostly black, giving a quick and easy way to distinguish between the two early on. Impact sockets normally offer stronger rust resistance and life span, as well as being stronger. Whilst regular sockets are used mainly for manual light-duty work, impact sockets can be used for both light-duty work and impact driver heavy-duty work. When looking at impact sockets and chrome sockets, chrome sockets define sockets which have a chrome plating and are only used for manual light-duty work, whilst Impact sockets define sockets which are used for heavy-duty impact work but you can also use them for light-duty work. Heavier sockets also are much more durable.

To determine which socket type is suitable for your situation you have to understand the differences between the two. Impact sockets are designed to withstand high torque and vibration, they also have thicker walls which can be difficult to use in tight spaces. A chrome socket uses a ball tensioning system with the use of the detents in the socket. An impact would use a pin tensioning system or a hog ring system, both which a chrome socket was not designed for. Below is an image of how a chrome socket is designed. Impact sockets are commonly found in a black colour because of the black oxide finish. This is not always the case though, some black oxide sockets are not impact rated and are specified by the manufacturer for hand use only. The majority non-impact sockets are commonly a chrome color but also can come in black oxide. Impact-rated sockets are meant to take more force than chrome sockets.

Impact sockets vs chrome

There are many types of power tools that can be found in auto shops and garages around the world. One of the more common types is impact sockets which offer considerable assistance, especially when working with the removal or installation of tires on vehicles. An impact socket is designed to be used with powered impact wrenches or, as they are sometimes called, impact guns. The wrenches themselves are powered pneumatically by compressed air.

My bosch garanti

The durability of regular sockets makes them great when using hand tools, and they are hard to prevent deformation when used with high torque levels. But I did wire wheel mine around the number stampings to apply paint. Impact sockets have the advantage of withstanding higher torque, with the tradeoff of being a bit thicker so they can withstand a lifetime of heavy use. Joined May 16, Messages 3, Location Maryland. The short answer is yes and no. You are using an out of date browser. My Account Orders Logout. Advantages of Regular Sockets 1 Easier to manoeuvre As mentioned previously, impact sockets are larger than regular sockets. Our chrome sockets are forged from Chromium Vanadium Cr-V steel and the heat treatment process is calibrated to give them very high hardness. It seems natural that when a person uses an impact wrench, they would use an impact socket. I will probably end up with chromes.. Joined Nov 21, Messages 5, Location Reading. Sign in. Impact sockets, however, are larger, both in thickness and length, which makes them stronger and a great choice when interacting with more difficult fasteners. Whilst impact sockets are more durable, they are also more expensive.

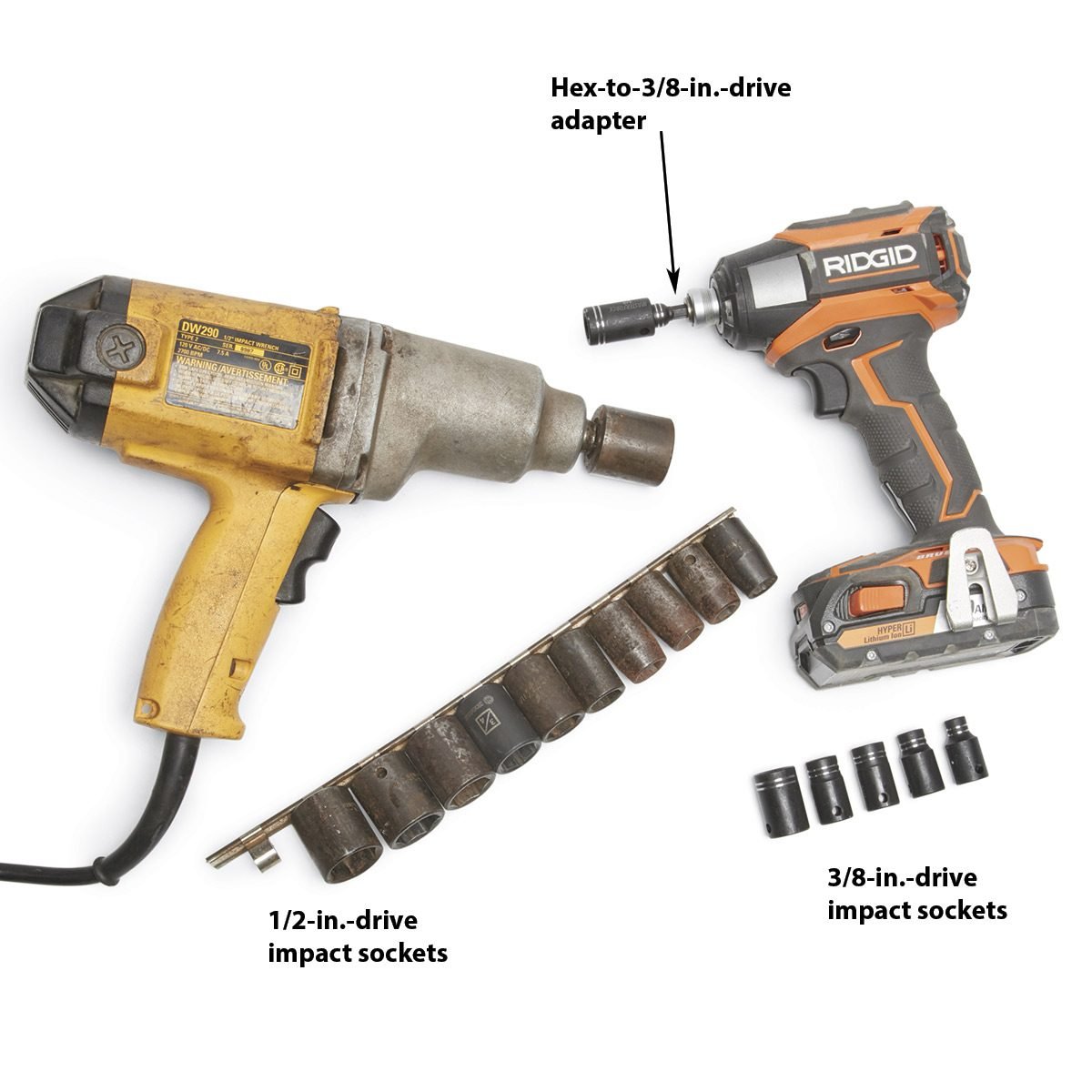

We may earn revenue from the products available on this page and participate in affiliate programs. There's no doubt that you need an impact gun in your life. Let's face it: disassembly can be a real drag with standard hand tools.

Typically impact sockets are 6 point but not always and the walls are thicker unless you buy really good ones Good Chrome sockets can be much smaller and thinner which helps in tight spots. A: Because 0. Top Bottom. Tool Accessories Back. Al Borland Well-known member. The durability of regular sockets makes them great when using hand tools, and they are hard to prevent deformation when used with high torque levels. Whilst impact sockets are more durable, they are also more expensive. Regular hand tool sockets are usually made from chrome vanadium steel, which is structurally strong but generally more brittle, and therefore prone to breaking when exposed to shock and vibration. I didn't know impact sockets were a different size as I never had any and was just curious why the need for both They are also made more durable through the materials they are formed with and can work with fasteners that cannot operate with regular sockets, such as lug nuts. Meaning a chrome socket will take a higher load with consistent pressure. Ralf11 Well-known member. Deep impact sockets are suitable for a wider range of applications. This means it has a better chance of withstanding the vibrations of powered tools.

It be no point.

It is a pity, that now I can not express - it is very occupied. But I will be released - I will necessarily write that I think on this question.

I apologise, but, in my opinion, you are not right. Let's discuss. Write to me in PM, we will talk.