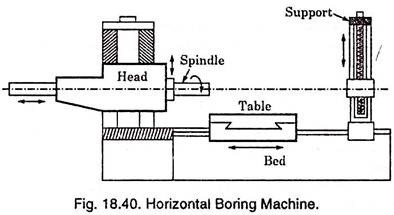

Horizontal boring machine line diagram

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article.

Horizontal 2. Vertical 3. Horizontal boring machine Milling, Grooving a. Floor Type c. Vertical Boring machine castings, fly wheels and circular parts a. Precision boring machine 4. Planner type.

Horizontal boring machine line diagram

Toll free Mills and lathes are highly versatile machine tools that form the centerpiece of most machine shop floors. Boring mills, on the other hand, are more specialized, meaning they frequently appear as part of a larger production line. The easiest way to describe what a boring mill does is to say that a boring mill drills holes. The reality is slightly more complex. Boring mills are more frequently used to enlarge holes that have already been drilled. While standard mills and lathes can also be used to rough out or finish boring holes, boring mills provide extra power and stability. This ensures a more precise finish to the hole itself and also preserves the dimensions of the piece. Boring mills operate on the same general principles as lathes, with a rotating spindle. Unlike lathes, boring mills are always used on internal geometries rather than the external geometries of a part. For example: a machinist could use a lathe to create a sphere out of a block of material.

Tolerances become less tight, cuts become less accurate, and the chance of failure becomes greater.

Download Now Download to read offline. Recommended Single Point Cutting Tools. Boring machine. Capston and turrent lathe. Capston and turrent lathe Yuga Aravind Kumar.

So, there are mainly 3 types of Horizontal Boring Machines —. The most versatile machine out of these above mentioned is the first one i. So, it is the most commonly used and universal type. A Horizontal Boring Machine has a work spindle parallel to the ground and work table. The tool head and part move typically along three linear axes. The main axis that drives the part towards the work spindle is the Z-axis, with a cross-traversing X-axis and a vertically traversing Y-axis. The work spindle is referred to as the C-axis and, if a rotary table is incorporated, its centre line is the B-axis. Horizontal boring machines are heavy-duty industrial machines. It helps in roughing out large components.

Horizontal boring machine line diagram

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine. Therefore, this is the main purpose for which the boring machine was developed. In addition to its primary purpose of boring, the range of speeds and feeds provided to the various traversing parts allow drilling, milling , and facing to perform with equal facility. By the fitting of simple attachments, the use of the machine can extend still further to include screw cutting, turning , planetary grinding , or gear cutting. In types of boring machines, the horizontal boring machine is one of the most useful and important machines.

Puerto rican bakery armory st springfield ma

Search inside document. Contents show. Recommended Single Point Cutting Tools. Table type HBM 2. The cutting tool mounts to the end of a rotating spindle, which is advanced into the workpiece. In a boring machine, for milling operation, any type of milling cutter may fit the spindle. A bed is made of cast iron and affixed on the ground. Unit 2 Unit 2. Nexus - Final Day 12th February Bed A bed is made of cast iron and affixed on the ground. The table is supported by a long bed on which it reciprocates. Holes are bored by using boring bars and tools. Horizontal 2. Skip carousel. Unit 3 Unit 3.

A horizontal boring machine or horizontal boring mill is a machine tool which bores holes in a horizontal direction. There are three main types — table, planer and floor. A horizontal boring machine has its work spindle parallel to the ground and work table.

What is Boring Machine? The end mill is used to produce grooves and slots. Tolerances become less tight, cuts become less accurate, and the chance of failure becomes greater. Horizontal vs. D Boring Machines: Salunke M. While standard mills and lathes can also be used to rough out or finish boring holes, boring mills provide extra power and stability. A headstock moves in an upward and downward direction for settling the operation tool on the required height of work. The table, saddle, and headstock may be adjusted by leadscrews using micrometer dials. The insert can also vary in size and shape, allowing operators to create different geometries and finishes with their boring mills. Drilling Machine Drilling Machine. The planer-type horizontal boring machine resembles the table type but the table slides directly on the bed instead of on a saddle angle to the spindle similar to a planer.

I apologise, but, in my opinion, you are not right. I suggest it to discuss. Write to me in PM, we will talk.

Completely I share your opinion. In it something is and it is good idea. It is ready to support you.