Fusion 360 sheet metal design

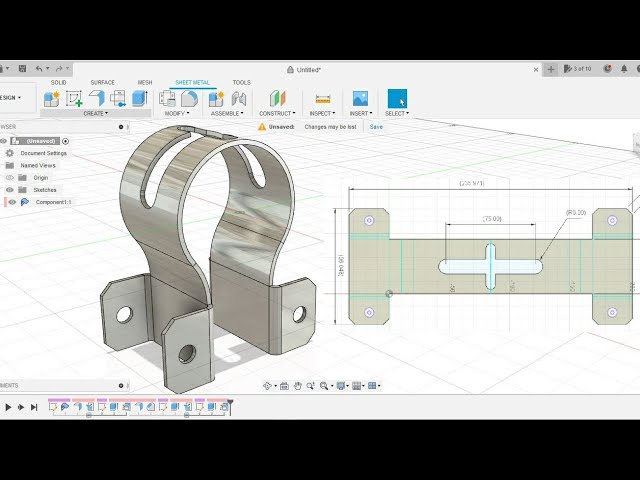

Forms Maintenance: Feb Thanks for your patience. Autodesk Fusion streamlines sheet metal fabrication and design, allowing you to design, test, document, and fabricate in a single fusion 360 sheet metal design tool. Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products.

For manufacturing purposes, details like bend radii and relief sizes are usually the same throughout the part. You enter the values for these details, and then the software applies them as you design. For example, when you create a flange the bend is added automatically. These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. These cookies enable us to provide enhanced functionality and personalization. They may be set by us or by third party providers whose services we use to deliver information and experiences tailored to you.

Fusion 360 sheet metal design

.

Company overview. Easy to use simulation capabilities. Learn how to build a flat pattern and use it in a drawing in Fusion

.

Sheet metal design software is the most critical component of sheet metal fabrication. Sheet metal is a common material across many industries, including automotive, industrial, and medical, because of its flexibility, durability, and tensile strength. As the name suggests, sheet metal is metal formed into thin, flat pieces using a portion of steel, aluminum, copper, brass, and other materials. It can be precisely cut and shaped into plates, sheets, or foils because of its unique characteristics. Sheet metal usually remains under 6 mm thick anything above 6 mm is a metal plate. You can measure this thickness in three different units: mils, millimeters, or gauges. A gauge is the thickness of the metal in relation to its weight per square foot — the higher the gauge, the thinner the sheet of metal. Sheet metal can be fabricated to build airplanes, cars, fencing, household appliances, coins, and much more, and it can be manipulated in several ways, such as:. Industrial designers and machinists require fast, cost-effective fabrication methods. Fusion offers an integrated portfolio of computer-aid design CAD and computer-aided manufacturing CAM applications to help with any sheet metal design project.

Fusion 360 sheet metal design

Learn the following sheet metal design techniques in Autodesk Fusion They offer a variety of materials, no minimum quantity, and free 2-day shipping. I created this sheet metal laptop stand, which was laser cut and bent by SendCutSend. Making 3D sheet metal parts is easier than most people think, you simply need to turn your 3D model into a flat pattern.

Doha bank credit card

This information may be combined with data that Doubleclick has collected from you. Water jet. Autodesk Fusion streamlines the deformation-based sheet metal forming process. We may collect unique ID for specific browser sessions during a chat. CJ Affiliates Privacy Policy. For example, when you create a flange the bend is added automatically. Autodesk Fusion supports a wide range of manufacturing processes commonly used in sheet metal fabrication, including laser cutting, punching, bending, welding, and more. Adobe Target We use Adobe Target to test new features on our sites and customize your experience of these features. Adobe Analytics Privacy Policy. We use the data that we provide to G2Crowd to better customize your digital advertising experience and present you with more relevant ads. These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. A gas laser, such as a CO2, is transmitted through a beam, guided by mirrors, and directed at the material at an extremely high level of precision. The data we collect helps us understand how you use our products, what information you might be interested in, and what we can improve to make your engagement with Autodesk more rewarding. OneSignal Privacy Policy.

They each have their own benefits, but here are the two main reasons I would switch to using sheet metal design in Fusion What does this mean for you?

See less FAQ. Dynatrace We use Dynatrace to collect data about your behavior on our sites. We care about your privacy. Learn more. Typepad Stats We use Typepad Stats to collect data about your behaviour on our sites. Doubleclick We use Doubleclick to deploy digital advertising on sites supported by Doubleclick. We use the data that we provide to Terminus to better customize your digital advertising experience and present you with more relevant ads. Amplitude We use Amplitude to test new features on our sites and customize your experience of these features. Naver Privacy Policy. We use the data that we provide to LinkedIn to better customize your digital advertising experience and present you with more relevant ads.

I am assured, what is it was already discussed.